Highway design is concerned with the principles and standards that public roads must adhere to. Effective design looks to deliver essential infrastructure which connects our towns and cities. It also encompasses other factors such as traffic flow, safety, cost and environmental impact, all of which we discuss below.

In this guide, we’ll take a closer look at what highway design involves, including early stages such as feasibility studies and surveys through to the preparation of contract documents. We’ll also explore some key highway design principles which need to be factored in, and consider important highway design standards that your projects must adhere to.

There’s a lot of ground to cover in this comprehensive overview. If you’re looking for something in particular, use the links below to navigate to it:

- What are the steps in highway design?

- Key factors to consider when designing a highway

- Specifications for highway design standards

- The value of geogrids in highway design

- Design and evaluate your highway projects with Tensar+.

Tensar provides a range of geogrids for roads and pavements, as well as solutions for earthworks and bridge structures. We offer advice and design support for ground improvement and soil reinforcement solutions using the most advanced geogrid technologies.

Our expert design team can provide a free Application Suggestion to show the value Tensar can bring to your project, from carbon savings to cost efficiencies. Get in touch today or request a design assessment to see how we can support your next highway design project.

What are the steps in highway design?

The stages in highway design may vary based on the location and scale of the project. Generally speaking, there are six steps to consider:

- Planning

- Right-of-way stage

- Preliminary design & Surveys

- Final design

- Construction

1. Planning

New roads and improvement schemes must comply with the planning procedures that apply in the country in which they are located.

During the initial planning stage, a project proposal will be put in place to determine the key requirements and expected outcomes of the project. The purpose of this stage is to build a viable case for stakeholders who have an interest in the project. This can include government agencies, local authorities and environmental agencies.

Generally, wherever in the world it is situated, any major highway design will require a public inquiry. This is a very formal procedure, which is usually reserved for significant developments or proposals of a sensitive nature, where all aspects of the development often need to be examined in detail.

Once these procedures have been followed and fully considered, a decision would then be taken on whether to proceed with a highway design scheme. Having received planning permission, engineers can then begin the detailed design of the road scheme. and preparation of contract documents.

Highway projects often face trade-offs between performance, cost, and environmental impact. Value Engineering provides a structured way to evaluate these trade-offs and justify decisions.

.png)

2. Right-of-way stage

With the planning and initial design complete, securing the right of way can commence. This step involves discussions around the acquisition of land and property rights for the highway project.

The main purpose of this stage is to ensure compliance with legal and regulatory requirements related to property acquisition. This will usually involve negotiation with land owners and local authorities. In some cases, compulsory purchase may be enforced if disputes are not resolved.

3. Surveys and preliminary design

Once the initial planning phase is completed, the highway design team can move on to carry out surveys and begin the preliminary design work. This is often conducted by a consultant who would independently prepare the preliminary design to enable a decision to be taken on where the road should be located within the preferred route envelope.

Across the globe, highway contracts are increasingly awarded based on preliminary design (of all or parts of the works). Contractors are responsible for the finished output under design and build contracts. This is common for bridgeworks and in some cases, pavement design. It allows contractors to make use of their own specialist expertise and equipment in the most economical way to meet the clients specifications. They will often employ external consultants to complete the detailed design.

Let's explore some of the different types of highway design survey carried our during the preliminary design stage and as the project progresses.

Topographical, environmental and geographical surveys

Topographical, environmental and geographical surveys are crucial to the preliminary design. Further information will be gathered from initial findings discovered during the planning phase, which will then inform conceptual designs.

This process helps to ensure the safety of road users and the protection of the local environment, all while keeping costs down for developers and project owners. The general layout, alignment and approximate dimensions of the highway will be drawn up based on the surveys, considering factors such as terrain, drainage and existing infrastructure in the local area.

Topographical surveys can be carried out by ground based instruments, drones or satellite imagery.

Topographical surveys can be carried out by ground based instruments, drones or satellite imagery.

Land surveys - Terrain mapping

Before work begins, a surveying company will be brought onto the site to conduct an initial land survey on the proposed site. Through this survey, they will assess things such as local terrain features, surrounding homes and infrastructure, grading and utility infrastructure beneath the surface.

Terrain mapping provides developers with the information they need to assess and plan the placement of a new road. Often using drones, terrain mapping captures detailed information about the land and area surrounding the proposed construction site. This can sometimes be turned into a 3D model, allowing design teams to make informed decisions on the placement and Geotechnical construction methods required.

Earthworks Surveys

Before construction can begin and after the final design proposals have been submitted, a land surveyor will carry out an earthworks survey, also known as volumetric surveying. This is used to determine the requirements for earthworks. See our guide on road construction to learn more about how earthworks are typically carried out.

Earthworks survey being conducted.

Engineering and construction surveys

Engineering surveys are carried out by assessing work that has been completed and comparing it to the original plans. By doing this, construction teams can identify issues and adjust accordingly so the finished project meets the design and safety requirements of the original plan.

Construction surveys can help identify issues.

Site investigation and geotechnical reports

The team will carry out a detailed site investigation along the full road length and prepare a geotechnical report, typically with the support of geotechnical engineers. In the detailed design phase, this will be used to determine the need for any ground stabilisation, for pavement design and the foundation of earthworks and major structures and bridgeworks.

Geotechnical reports help to determine the need for any ground stabilisation for pavement design.

Geotechnical reports help to determine the need for any ground stabilisation for pavement design.

We're here to support with the design of your next highway project

Our design team is available to assess all different types of highway design schemes worldwide to determine whether they can benefit from using our geogrids, asphalt reinforcement, slope stabilisation and retaining wall system solutions.

Tensar can support you in identifying the most viable solutions for your project and outlining the benefits in terms of cost and carbon savings.

4. Final design

The final design is an opportunity to refine the preliminary designs that were drawn up in the previous stage, including more detailed plans and specifications.

During this stage, specific engineering challenges will be addressed such as earthworks and drainage design, pavement design and the design of major structures and bridgeworks. Depending on the location of the proposed highway, utility companies may be consulted to accommodate underground infrastructure.

In addition to this, the design team will address health and safety considerations and local construction management regulations.

5. Construction

The final stage is the construction of the highway. The exact highway construction process will depend on the techniques and methods used, as well as the construction company and client.

Constructing a road is a complex process involving careful planning, stringent regulatory compliance, and coordinated efforts from multiple stakeholders. Explaining the steps involved is beyond the scope of this guide – to discover more, see our article on .

The construction company awarded the contract may consider alternative solutions and designs that could offer greater economy or more rapid construction. Such alternatives would need to be approved by the client.

Key factors to consider when designing a highway

Highway authorities must consider multiple factors when planning a new highway. National, regional and local needs, and impact must be addressed and balanced. These factors include traffic flow, user safety, pavement life, storm water management and any potential environmental impact.

Geometric design

Geometric design is a field within highway engineering that focuses on the location and alignment of a roadway design. This includes consideration of pavement widths, horizontal and vertical alignment, slopes, intersections and other features that can significantly affect the operations, safety and capacity of the highway network.

The geometric design of a road meets the characteristics and requirements of a highway, whilst also accommodating the needs of its users.

Horizontal alignment

Horizontal alignment takes into account the curvature of the road and straight sections while considering location of the roadway in relation to the surrounding areas.

Effective horizontal alignment aims to reduce sharp corners to provide clear sight lines, helping to provide safe and efficient travel. Design engineers will consider a range of criteria such as design speed and curve radii and transition length, which are explored in greater detail below.

Vertical alignment

Vertical alignment is the side view of a road’s profile and considers gradients and the different elevations along the road. Vertical alignment aims to reduce steep gradients to provide appropriate site lines which enhances safety and travel for users.

Vertical alignment consists of straights connected by parabolic curves, which need to be provided at all changes in gradient. The parabolic curves can be divided into two groups: crest and sag curves. A crest curve is a curve used when the change in grade is negative, for example, hills. On the contrary, a sag curve is a curve used where the change in grade is positive, for example, valleys. Both types of curves are defined by three major points: Point of Vertical Curvature (PVC), Point of Vertical Intersection (PVI), and Point of Vertical Tangency (PVT).

Pavement design

Pavement design is one of the most important components of highway design. The pavement should provide a smooth and durable surface which is capable of withstanding the volume and type of traffic it may encounter.

The type of pavement and the required design life, will have a significant impact on the overall project cost as well as future maintenance requirements and cost.

Pavement structures fall into two main categories, rigid pavements, and flexible pavements. The design methods available for each of these types are quite different – see our road construction guide to discover more.

We've got vast experience in pavement design

Tensar has considerable expertise in collaborating with contractor's project teams to investigate and evaluate alternative solutions pavement design.

If this could be useful for a project you are working on, our team can offer a free Application Suggestion to show what Tensar solutions can achieve and how much value can be added to your project.

.jpg)

The design of highway structures

The design of bridges and other highway structures is governed by local regulations, however some general stages are universally applicable.

The first step is to model the structure’s mechanical skeleton, including its foundations, columns, beams, frames, trusses, and other elements. The start point is the architectural model. An architectural model shows what the structure will look like in reality, but it is not suitable for calculations due to the high level of detailing. The architectural model needs to be stripped until only the load-bearing structure remains. The load-bearing structure will transfer the applied loads to the ground.

Translating the load-bearing structure to a model ready for calculations is called schematisation or creating the wireframe model, the mechanical model, or the plan of the model.

Furthermore, modelling involves determining the structure’s material, whether it would be structural steel, reinforced or prestressed concrete, timber, or composites. The choice depends mostly upon the economy and safety of a structure.

Modelling also involves assuming dimensions for each element which is the basis for self-weight computation for the load analysis. Estimating the member size includes what should be the element width, the depth or the thickness. Rules of thumb can be used for the choice of the initial dimensions.

Load analysis

Next, the structural engineer must identify all possible loads that the structure may experience during its lifetime. Examples of loads on structures are:

- Dead loads - meaning the self-weight of the structure

- Live loads - moving equipment, and the movement of cars on bridges

- Wind loads - any horizontal, uplift or shear pressures or forces that the wind exerts on a structure

- Snow loads - only applicable for structures expected to receive snowfall

- Seismic loads - when the structure is in a seismic region

- Earth pressure - to be applied for retaining walls and bridge abutments

- Water and ice - for some structures such as bridges, offshore platforms, and coastal structures

- Thermal loads - unequal heating or cooling of parts of the structure create high stresses

The values of these loads can be identified using appropriate structural design codes and references.

In reality, different loads act simultaneously on the structure. The combination of the various loads should be evaluated. For instance, a simultaneous action between dead load (weight of the structure) and live load (use of the building by people) can be a load combination. But also, dead loads and wind loads can be a combination. Usually, structural engineering software will automatically create a set with all possible load combinations.

Bridge abutment and wing wall design

A typical overbridge will have approach embankments raising the road up to bridge deck level. The deck is supported on bank seats at each and possibly by columns mid span. The bank seats have traditionally been supported on columns that carry the bridge load down into the foundation. The foundation may be piled or a reinforced concrete raft.

Abutment walls and wing walls support the approach embankments, creating a vertical face to reduce the embankment footprint beneath the bridge.

Historically, abutment and wing walls were constructed of masonry, reinforced concrete or steel piles. But today, reinforced soil structures with concrete block or panel facing are likely to be chosen due to their economy, speed of construction and lower carbon emissions.

In recent times, more and more design engineers are choosing to support the bank seat directly on the reinforced soil block, transferring all bridge loading into the reinforced soil structure. TensarTech Retaining Wall Systems offer major cost savings and reductions in construction time compared to supporting the bank seat on columns or load bearing reinforced concrete abutments.

Earthworks and embankment design

Roads are often constructed above the existing ground level. This could be to raise the road approaching an overbridge, to accommodate the vertical alignment design, or to elevate the road above a flood plain.

In some cases, particularly in urban areas, the road may be supported on columns, but in most cases an earth embankment will support the road. Geotechnical engineers will design the embankment to ensure stability of the side slopes and foundation soil.

The side slopes of embankments can be steepened using TensarTech Reinforced Retaining Wall System to reduce the embankment footprint and minimise land take.

Constructing embankments of weak soils presents a challenge. Tensar Foundation and Embankment support systems allow embankments over weak ground to be built rapidly and at a lower cost than alternative foundation support methods.

The Benefits of Reinforced Soil Retaining Walls

Our internationally-certified reinforced earth wall systems and products provide options of architectural and natural finishes, as well as design and component options for easily-built curves and terraces. Tensar’s full design service includes working drawings, material schedules and method statements to help your business.

.jpg)

Specifications for highway design standards

Every country has a different highway design process, along with associated regulations and standards.

In the UK, for example the relevant standards for National and Local Authority roads is the 'Design Manual for Roads and Bridges (DMRB)' – CD225 (Foundation design) and CD226 (New Pavement design) are key parts of this. Based on the trafficking capacity, each national or local road will have a Foundation Class and there are four categories of Foundation Class. Tensar would usually provide designs and supply for Foundation Class 1 & 2 schemes (Local Authority roads) where unbound aggregates can support the surfacing.

In Europe, Structural Eurocodes establish a common set of standards throughout Europe for the design of civil engineering works, including bridges and other highway structures. Their implementation has introduced a wide-ranging change to the codification for structural design.

Regulations need to be reviewed constantly and are often changing. In Germany, for example, In recent years, the regulations for the design of rural roads have been fundamentally revised. The regulations, previously divided sectorally into alignment (RAS-L), cross-section (RAS-Q) and junctions (RAS-K-1), were merged into an integrated guideline for the design of rural roads (RAL).

The Guidelines for the Construction of Rural Roads (RAL) form the basis for all planning and designs for the new construction as well as the conversion and extension of rural roads in the charge of the federal government.

The value of geogrids in highway design

Geogrid pavement design is a new and innovative approach to constructing optimised road pavements, leveraging geogrids to enhance performance and longevity. Tensar geogrids are engineered materials integrated into pavement layers, providing mechanical stabilisation to aggregate materials.

This design methodology aims to strengthen the pavement, minimising rutting and fatigue cracking which can lead to the formation of potholes. . Geogrid pavement design proves essential for a range of flexible pavements, ensuring durability and performance.

A geogrid consists of a 2-dimensional arrangement of integrally connected tensile elements or ribs that form a grid or net-like structure, usually supplied in roll form. Manufactured from polymers, geogrids are classed as geosynthetic products; this is a broad product classification that includes geotextiles and geomembranes alongside other minor categories.

Tensar geogrids are typically manufactured from oriented high-density polyethylene (HDPE) or polypropylene (PP) for durability, stiffness and strength. The junctions between ribs are integrally formed giving them high strength and structural stability. The design quality and effectiveness of Tensar geogrids has made them the go-to solution for local authorities in the UK and around the world.

Polymeric geogrids are used to solve civil and geotechnical engineering problems in or on the ground. They primarily provide a soil stabilisation or reinforcement function, to add to or enhance the properties of soil or aggregate materials.

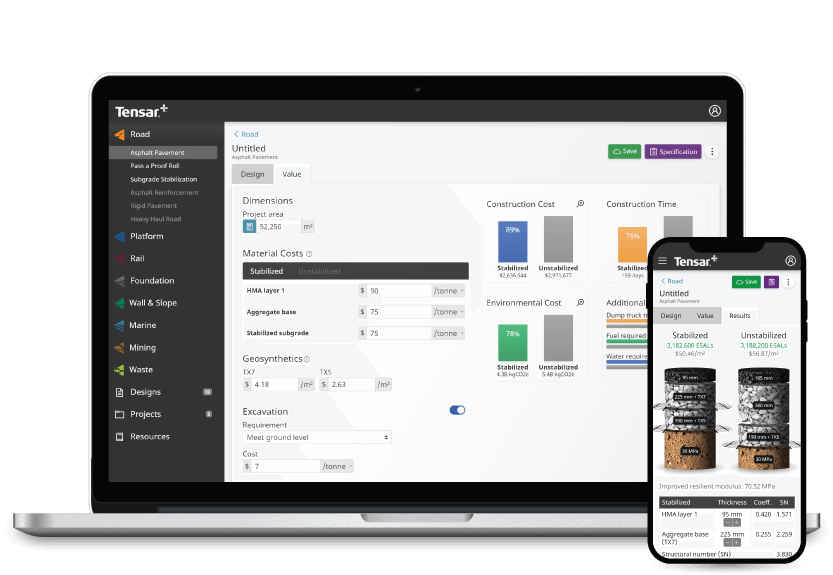

Design and evaluate your highway projects with Tensar+

Our software can be used to design your highway project, customise its specifications and see the cost-savings in real time, no matter where you are based in the world.

The Tensar+ geotechnical design software platform enables you to:

- Design and evaluate project specs

- Compare alternative materials and project conditions

- See the cost and time savings in real time as you change parameters

- Analyse the sustainability of your projects.