Highway construction is a vital area of civil engineering that’s typically managed by government authorities in collaboration with road construction companies.

Highways remain the bedrock of all transport systems around the world. They enable people and goods to travel in a wide variety of different ways, connecting the country and providing access to homes, businesses, jobs, shops, education, healthcare, leisure, and international gateways.

This comprehensive guide takes a close look at the different stages of highway construction and explores the challenges that contractors, engineers and local government agencies face. Read on for expert advice on how to build durable highways that stand the test of time, significantly reducing maintenance costs and providing ongoing sustainability benefits.

Depending on your role in highway construction and current level of knowledge, you may find certain parts of this guide more useful than others. Use the jump links below to navigate to the sections that interest you most:

- The significance of highway construction projects

- The different stages of highway construction

- Highway construction in action: FARRRS

- Common challenges faced during highway construction

- Design and evaluate road-build projects with Tensar+

Tensar provides a range of solutions that design engineers can use to extend the lifespan of highway construction projects, offering substantial, quantifiable cost and carbon savings. If this could be useful for a project you are involved with, speak to our team for a free consultation.

The significance of highway construction projects

The aim with any highway construction project is to connect two or more areas together to enable reliable and safe movement of people and goods, delivering a smooth and consistent driving experience. Better connections support individual towns and cities and strengthen the country as a whole: in the UK, for example, roads carry 88% of all passenger miles and 79% of all freight moved.

Highway authorities and road operators, whether local or national, face the task of building and maintaining the roads in their communities. Engineers designing new roads and public road improvements seek to deliver safer, better, longer-lasting roads more economically, more sustainably and with greater resilience. Specially designed geogrids for roads, such as Tensar’s InterAx® geogrids, can be used to help achieve this.

The different stages of highway construction

As we’ve seen, highway construction involves many different stages. The exact stages can vary from project to project depending on requirements, however, there are some fundamental processes that most highway construction projects will follow:

Highway planning and design

Before construction starts, rigorous planning, preliminary design, and final design stages must be completed to ensure highway safety. The preliminary highway design stage involves determining the alignment, grades, and widths of the roadways and intersections. The final design stage takes into account all the details of the road construction, including pavement design, drainage systems, and signage.

The process of designing a road will consider the amount of traffic that will use the road, the types of vehicles using it, the land it is built on and the effect it will have on things like noise, pollution and wildlife as well as safety challenges and designing and planning a road so it can be resilient in the future.

More road authorities are demanding planners, developers and contractors design and build new roads in accordance with their climate change resilience objectives and or carbon reduction commitments. To help meet these sustainability targets, design engineers will often use geosynthetic solutions such as geogrids.

.png)

Site investigation

The main reason for site investigation is to understand in detail the ground conditions for your site before works begin so that any risks can be considered along with the construction methods needed.

A ground investigation is essential for gathering factual data for the underlying geology and groundwater levels, that can be interpreted for geotechnical and geo-environmental purposes across a wide range of projects.

It is estimated that around 80% of problems discovered on construction projects are attributable to unexpected ground conditions that would have been spotted and avoided had an adequate site investigation been carried out.

A good site investigation allows designers to accurately calculate subgrade strength, and identify locations of weaker areas. This is essential to ensure that a safe, efficient, cost-effective design is achieved. A Tensar geogrid can be incorporated to improve soil strength and further reduce design and maintenance costs.

Earthworks and excavation

This stage involves removing obstacles from the site, such as trees or rocks and levelling the area to prepare the subgrade for the construction of the road foundation layers. Some of the materials removed may remain on-site to be used in backfill which is known as the “cut and fill” method.

The ‘cut-and-fill’ process is typically used for earthworks in road construction. First, the material is excavated from the site. It is then transported nearby and used to create embankments. The cut-and-fill method minimises the amount of construction labour and conserves the excess material reducing soil disposal.

Tensar geogrids can be invaluable in reducing the amount of unsuitable material that has to be excavated during this phase of highway construction. They are capable of stabilising site-won aggregate through an interlocking mechanism, so material can be recycled rather than having to be transported away. This approach offers additional sustainability benefits because the thickness of aggregate layers can be reduced, so less material is required overall.

Road construction

Once the design, surveying, and excavation are complete, the team can begin to build the layers that make up the structure of the highway. The road foundation comprises the subgrade, lower foundation layer and/or the upper foundation layer.

The subgrade is the starting or formation layer onto which the road construction will be placed and it must be carefully prepared to ensure that the highway is safe and durable. Once the subgrade is properly prepared, the next stage of the highway construction process can begin by building the road foundation.

The road foundation is typically formed by using layers of unbound granular material. Terminology for these layers can vary regionally. If the subgrade soils are weak, then a “lower” foundation (capping or sub-base) layer would be used utilising a lower quality material to minimise the required thickness of the more expensive "upper" foundation layers (sub-base). This lower layer would provide protection to the weak subgrade during construction operations and support to the layers placed above.

The “upper” foundation layer would use higher quality granular material (sub-base or base) to form a platform on which the main structural layers of the whole of the road are constructed. Where there is no need for a lower foundation layer, the upper layer can be placed directly on the subgrade formation.

-(1)-(1).jpg)

In this road structure diagram, note that Tensar geogrid can be used between the subgrade, capping, and subbase layers to construct stronger highway foundations that perform well over time.

Construction of the aggregate layer

After the earthworks and grading have been completed, the construction of the aggregate layer can begin. The aggregate is then compacted to solidify the base, providing a strong foundation for the paving layer to be constructed on top.

During this stage of construction, geogrids can be used to stabilise various types of aggregate. This is where a mechanically stabilised layer is formed to act as a lower layer or a stabilised upper layer, or both.

The addition of one or more mechanically stabilised layers strengthens the foundation, improving the performance and design and extending the lifespan of the finished road. It also provides options to reduce the thickness of the road, allowing highway construction project teams to benefit from decreased costs and environmental impact.

Construction of the pavement layer

The final stage of constructing a highway is to build the road surface or pavement layer. This will act as the upper layer of the road pavement, serving as the interface between vehicles and the underlying structure.

The pavement layer is a critical component that needs to withstand the impact of traffic, weather conditions, and other environmental factors, whilst also providing a smooth, safe driving experience. The process involved in constructing it largely depends on the type of pavement that will be used.

If a flexible pavement is chosen, then the first layer of asphalt is the asphalt base which then has asphalt surfacing layers placed on top. The type of asphalt and mix methods used will rely on both the environmental characteristics of the area and the intended usage of the road.

For rigid pavements, a reinforced or unreinforced in-situ concrete slab is laid over the granular sub base. The thickness and strength of the concrete slab will depend on factors such as traffic volume, expected load, and climatic conditions of the region. It is important to choose the right kind of pavement as it affects the durability, performance and maintenance costs of the highway.

See our guide on the different materials and types of road surface that are used for highways to learn more.

FARRRS

Doncaster, UK

Incorporating Tensar Geogrid in the road subgrade delivered a thinner, and better performing, pavement for a major new highway in Yorkshire.

Benefits

- £500,000 construction cost savings

- 7,000 tonnes of material savings

- 26% reduction in overall pavement thickness

- 60% average increase in road service life

Common challenges faced during highway construction

Due to the nature and scale of highway construction projects, it is not uncommon to face certain challenges throughout the process. These challenges can include the safety of workers, traffic management, disruption for local communities, environmental concerns and changes to the soil composition.

Traffic management

Sometimes, highway construction requires the closure of certain roads to allow for the construction work to take place. This is especially true for road improvement projects and rehabilitation work. As the diversions disrupt the normal flow of traffic, construction companies may have to face tighter deadlines to reopen the road networks.

Traffic management on work-sites has improved dramatically over the last few years with a number of innovations including equipment like automated cone laying machines and automatic barriers, which in some cases, can be solar powered.

Disruption to surrounding communities

Along with traffic management challenges, this often increases disruption felt by local communities. For example, if work is carried out during peak rush hour, this can lead to delays and frustration among road users. Similarly, this can also increase risk for the construction workers.

Some road construction and maintenance techniques have been developed to improve this. Some surface treatments, for example, can be completed at night, meaning less disruption to the public and less safety risks to the operatives.

Environmental concerns

Due to the sheer scale of highway construction projects, there are numerous challenges which pose risks to the local environment.

Recycling of aggregates goes a long way towards managing this environmental problem, and is a solution that many road construction companies have adopted in recent years. Recycled aggregates are reprocessed aggregates derived from demolition or construction waste. Rather than harvesting new sand, gravel, or crushed stone, recycled aggregates contribute to a circular economy by repurposing reclaimed material and waste.

The Tensar geogrid range can be used to enhance the performance of such recycled aggregates, adding further to the resilience of the road construction.

Design and evaluate highway construction projects with Tensar+

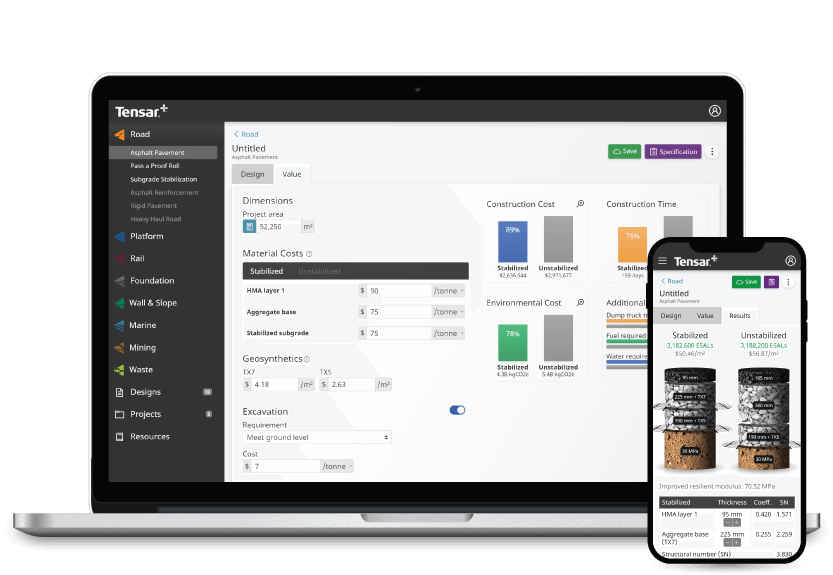

With the road design and construction module in our geotechnical software platform, Tensar+ helps design engineers visualise, prepare, understand and evaluate the parameters and requirements of road construction projects. Tensar+ and Tensar geogrids can enhance your road construction projects.

Tensar+, our free, cloud-based geotechnical design software, allows engineers, contractors, and owners to design with geogrid in a variety of applications. The newly enhanced design solution features a simplified user experience with all the features engineers have come to expect and depend upon with Tensar geotechnical software.