Laterite and Lateritic Soils: Definition & Characteristics

by Andrew Lees, on August 29, 2024

Lateritic soils are a distinctive type of soil commonly found in tropical regions across the globe. These soils, which undergo a process known as laterisation, are known for their rich mineral content and adaptability, making them a crucial resource that’s often used in road construction and the design of reinforced embankments.

In this blog, we'll explore what lateritic soils are, how they differ from laterite (a reddish clayey material with a gravel component), how they’re formed through laterisation, their unique properties, and their practical applications in construction.

Use the links below to navigate to the sections you’re most interested in:

- What are lateritic soils?

- What is laterite?

- What is the difference between laterite and lateric soil?

- The laterisation process

- Laterite soil characteristics

- Uses of laterite in construction

- How Tensar can help

Considering whether lateritic soil would be suitable for an upcoming soil wall or steep slope construction project? Speak to our team for a free consultation.

What are lateritic soils?

Lateritic soils are highly weathered residual soils found in tropical and sub-tropical regions, formed as a product of the laterisation of rock. The colour of lateritic soils ranges from dark reddish brown, through rusty red, to purple. There are many physical forms of lateritic soil. Particle size can range from clay/silt to sand/gravel. As a result of laterisation the particles are typically coated with sesquioxide concretions, giving cementitious characteristics.

Andrew Lees visits the Cu Chi tunnels in Ho Chi Minh City, Vietnam to tell us about lateritic soils.

What is laterite?

Laterite is a clayey material that is hard when dry and accumulates as topsoil in tropical and subtropical regions. Like lateritic soils, laterite is recognisable by its red, brown, and purple tones.

There are three types of laterite:

- Wormhole laterite – a concretionary formation that’s rich in iron and gets its name from the fact that it looks like a wormhole.

- Pellet laterite – pellet-shaped particles of the material, cemented together by iron-oxide.

- Doughy laterite – a soft, dough-like that forms in tropical climates by heating and drying.

What is the difference between laterite and lateritic soil?

The key difference between laterite and lateritic soils lies in their physical composition: lateritic soils are fine-grained materials, whereas laterite contains larger particles and has a gravel component.

The difference between laterite and lateritic soil has been a topic of debate since the term "laterite" was first introduced by Buchanan in 1807, when he used it to describe a material he saw being used for brick making in Malabar, India. He described the material as having soft consistency in-situ but hardening rapidly on exposure to the air. In fact, the name laterite derives from the Latin word for brick – ‘later’.

.png)

Laterite bricks being sourced from a quarry in Goa, India (Source: Wikimedia Commons)

Laterite has been given various definitions over the years. It is probably safe to say that laterite is the result of complete (or mostly complete) laterisation of rock. In a laterised soil profile, the topmost layer of residual material – immediately below any topsoil – may become laterite given time, thought to be a geological epoch of roughly a million years.

Fermor, way back in 1911, suggested that a residual material with 90% or more ‘lateritic constituents’ could be considered a true laterite. Residual material that has not completely laterised, but has released silica, has sesquioxides fixated to particles, has no accumulated organic matter and had the reddish brown to rusty red colour, should be characterised as lateritic soil. We could say that a lateritic soil is on the way to becoming laterite, given the right conditions and geological time.

Laterite, then, typically forms from the complete weathering of rock, resulting in a hardened, iron-rich material. In contrast, lateritic soil refers to the residual material that has undergone some degree of laterisation but has not yet reached the full stage of laterite. This soil often retains significant amounts of silica, has sesquioxides (primarily iron and aluminium oxides) and exhibits a reddish-brown to rusty-red colour.

Lateritic soil can be seen as a transitional phase on the path to becoming laterite, given the right conditions and sufficient time. While laterite represents the end stage of the laterisation process, lateritic soil shows an intermediate stage of development.

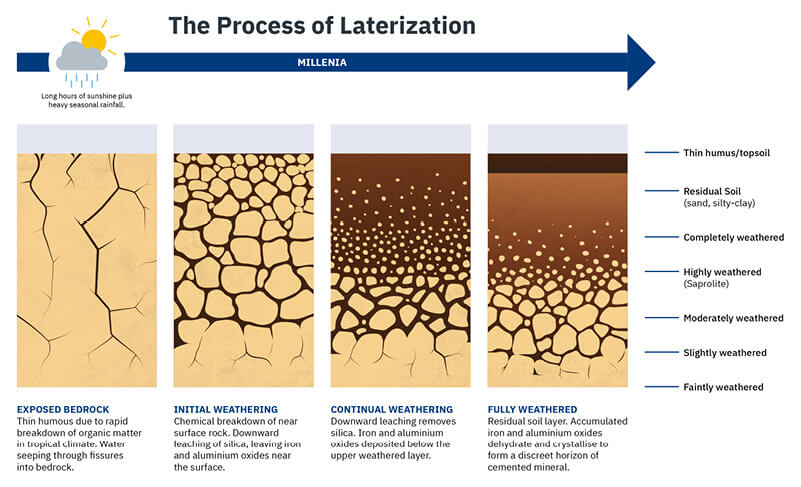

The laterisation process

Laterisation can occur when parent rock, rich in alumina, iron and silica, is subjected to weathering in regions with moderate to high temperatures and distinct wet and dry seasons. There are three stages of laterisation:

- Initial Weathering - The parent rock begins to weather and superficially decompose, becoming increasingly porous.

- Leaching and Deposition - Organic material, silica, lime, nitrogen, phosphate, and other mobile elements are leached out during successive cycles of wet and dry seasons. Meanwhile, sesquioxides — primarily iron (Fe2O3) and aluminium (Al2O3) — are deposited. These accumulated compounds, known as 'lateritic constituents,' progressively enrich the soil.

- Dehydration and Crystallisation In the final stage, the accumulated materials undergo dehydration and crystallisation, solidifying the transformation.

For laterisation to occur, the rock's interstices must become saturated during wet seasons and dry out completely during dry periods. The process often remains incomplete, with materials existing at various stages between parent rock and fully developed soil. This gradual transformation typically results in blended horizons within the soil profile, showcasing the complexity of lateritic soil formation.

-(1).jpg)

The Laterisation process

Lateritic soil characteristics

The characteristics of lateritic soils are dependent upon the synergistic effect of a variety of factors, including the parent rock composition and morphology, rainfall intensity, temperature, hydrology, topography, and depth within the soil profile. Lateritic soils can exhibit the properties of both cohesive and non-cohesive soil: silt and clay-based lateritic soils exhibit cohesive behaviour, whilst those with predominantly sand/gravel size particles exhibit non-cohesive behaviour.

Due to the substantial variation in their geotechnical characteristics, lateritic soils are described in general terms rather than as a specific classification in geotechnical engineering. This broad variability means that while the term is useful for general discussions, it is not suited for precise soil classification in engineering applications.

Uses of lateritic soils in construction?

Lateritic soils are highly versatile and can be effectively utilised in various construction applications. Their unique properties make them suitable for a range of engineering projects, including road construction, embankments, and structural fill. With advancements in soil stabilisation techniques, lateritic soils offer both strength and durability, proving to be a valuable resource for diverse building needs.

Bricks

Lateritic soils are widely used for brick making. This has been done for centuries. In the most basic form, bricks are cut and shaped from the soil profile and left to dry and harden. In some cases, the lateritic soil is reformed in moulds and compressed into hard bricks. The addition of cement or lime greatly improves performance. The strongest, least moisture absorbent bricks are produced by moulding and firing. This process ensures durability and improves the overall quality of the bricks.

Road construction

Lateritic soils have long been a staple in road construction throughout tropical and subtropical regions. Their performance is greatly influenced by climate, drainage and compaction density. Lateritic soils have unique properties that make them different from other road-making materials. This often results in their rejection for use based on conventional testing and specification requirements. Yet despite this, their performance in service has been proven to be positive.

To address these challenges, many countries have developed specific standards for lateritic soils. In recent years, medium-quality lateritic soils have been successfully used for road base and sub-base layers, particularly when stabilised with cement, lime, or rice husk ash.

Mechanical stabilisation of lateritic soils is another option. Parock et al (2013) describe the use of geosynthetics such as Tensar geogrids as a cost-effective alternative to chemical stabilisation. These polymer-based solutions can improve the bearing capacity, shear strength of soil, and overall stability of soil. They are particularly effective in applications such as reinforced soil retaining walls and reinforced slopes.

For advice on the use of geosynthetics to solve civil and geotechnical engineering problems, speak to our team today.

Earthworks

Lateritic soils are widely used in embankment construction and the backfill of structures. Their advantageous properties make them a popular choice for structural fill in reinforced soil structures. Compacted lateritic soil demonstrates high strength, low compressibility, and low permeability of soil, making it an excellent material for foundation systems and embankment stabilisation.

Academic literature highlights some important considerations to take into account if you are considering an engineering project that makes use of lateritic soils. Erlich and Becker (2010) reporting on their use in reinforced soil structures in Brazil note that the compacted lateritic soil has high strength, low compressibility, and low permeability. Gouw (2016) reports that lateritic soils are often used as fill in reinforced soil structures in Indonesia. He warns that compaction should be undertaken in drained conditions.

For advice on the suitability of lateritic soils in TensarTech reinforced soil retaining walls and steep slopes, contact us or head to the Tensar design support page.

How Tensar can help

In this article, we’ve explored the characteristics of lateritic soils (distinguishing them from laterite), how they can be used in construction, and some of the complexities and challenges that can arise from doing so.

If you have an upcoming project that involves the use of lateritic soils, geosynthetic solutions could help you to reduce overall costs through mechanical stabilisation. Speak to our team for a free consultation.

References

• Netterberg, F. 2014. Review of Specifications for the use of laterite in road pavements. ANSARA

• Kumar, G.S., Saini, P.K., Deoliya, R., Mishra, A.M., Negi,S.K., 2022. Characterization of laterite soil and its use in construction applications: A review. Resources, Conservation & Recycling Advances Journal. Elsevier

• Parrock,A., Pleissi, L.L.L., James, G.M., Roe, T., Cook, J., 2013. Designing Cost-effective, Geosynthetic-reinforced Pavements in Equatorial Africa Utilising 2-D Axi-symmetric Finite Element Analyses. GhIGS GeoAfrica 2013 Conference. Accra

• Gouw,T.L., 2016. Common Mistakes in Designing MSE Wall with Finite Element Method. Geosintetik Conference. Indonesia.

• Ehrlich,M., Becker,L.D.B., 2010 Reinforced soil wall measurements and predictions. 9th International Conference on Geosynthetics, Brazil

.png?width=400&height=400&ext=.png)