Stabilised Gravel Rafts: Mitigating Seismic Liquefaction Damage to Buildings

Mechanically stabilised gravel rafts have been proven to limit differential settlement during seismic events, when liquefaction could otherwise lead to high levels of damage to buildings. As well as removing the need to completely demolish and replace compromised buildings, gravel rafts are also a crucial measure to reduce the threat that catastrophic soil liquefaction can present to human life.

Developers and engineers need to know that an evidence-based foundation solution is available that can mitigate the damage to housing and other low-rise structures. By restricting the differential settlement that could otherwise be brought about by seismic activity, stabilised gravel rafts greatly reduce the damage to structures, helping them to maintain structural integrity. In most cases only minor repairs are needed to reinstate the buildings.

In this guide, specialist geotechnical engineer, Andrews Lees, offers an in-depth look at the role that gravel rafts can play in mitigating building damage from seismic liquefaction. Read on to discover how design engineers can use deep or shallow foundation techniques when constructing on liquefiable ground – plus the real-world validation that supports the use of geogrid-stabilised gravel rafts.

- Introducing seismic liquefaction events

- How to mitigate damage to buildings

- Ground improvement techniques for reducing differential settlement

- Designing a geogrid-stabilised gravel raft

- Real-world validation of the stabilised gravel raft over liquefiable soils

What do we mean by seismic liquefaction events?

When loosely packed, water-saturated soil is shaken during an earthquake, it rapidly loses strength and behaves like a liquid. Any buildings on the surface will settle into the liquefied soil. These settlements will not be uniform, resulting in expensive structural damage. See our guide to soil liquefaction to discover more.

How to mitigate damage to buildings

When liquefaction occurs beneath a building during an earthquake, the building rocks back and forth due to the lateral seismic movements. This results in uneven settlement across the building. It is this non-uniform settlement that causes extensive structural damage to buildings. If settlement can be made more uniform across the building foundation, then building damage can be limited, potentially requiring only minor repair.

Ground improvement techniques for reducing differential settlement.

There are two categories of ground improvement commonly used to reduce differential settlement during liquefaction: deep and shallow techniques.

Deep foundation techniques

One such deep foundation solution is rammed aggregate piers (RAP). With this type of ground improvement, successive lifts of aggregate fill are rammed into a shaft pre-formed by a hollow mandrel pushed down into the soil. The aggregate is forced outward during the ramming process, imparting high lateral stress on the surrounding soil. Multiple piers are installed at a regular spacing across the area to be improved. The RAP reinforced ground has been shown to have improved liquefaction resistance. Further information on Geopier rammed aggregate piers is available from Geopier a Division of CMC. .png) Figure 1 – Construction of a Rammed Aggregate Pier for ground improvement (Source – Wissman et al, 2015, Rammed Aggregate Pier Ground Improvement as a Liquefaction Mitigation Method in Sandy and Silty Soils)

Figure 1 – Construction of a Rammed Aggregate Pier for ground improvement (Source – Wissman et al, 2015, Rammed Aggregate Pier Ground Improvement as a Liquefaction Mitigation Method in Sandy and Silty Soils)

Shallow foundation techniques

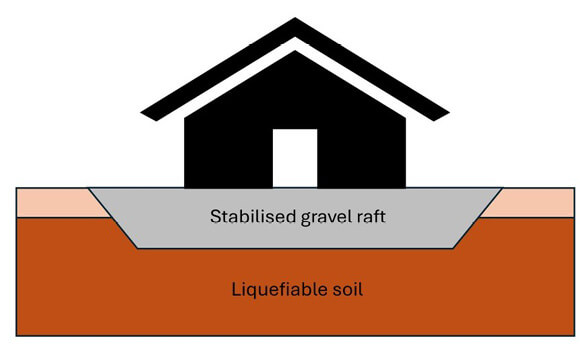

With these techniques, a non-liquefiable ‘crust’ is created above the liquefiable soil. This increases the bearing capacity of the soil and prevents the surface manifestations of liquefaction. Shallow techniques are more economical than deep techniques for the mitigation of differential settlement in low-rise buildings and housing. One commonly used shallow technique is the geogrid-stabilised gravel raft. More on this below.

.jpg)

Figure 2 – Stabilised gravel raft foundation for mitigation of liquefaction.

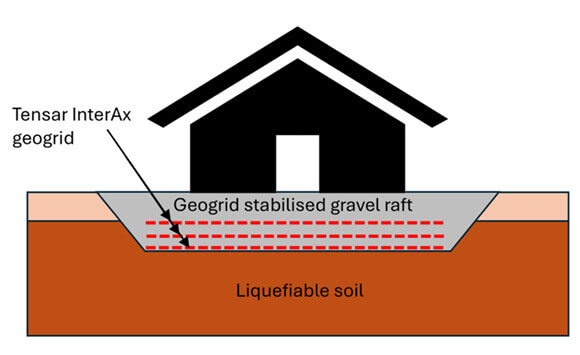

Geogrid-stabilised gravel rafts

When a suitable geogrid is incorporated into a layer of gravel, the gravel particles interlock with the geogrid to form a mechanically stabilised layer. Multiple layers of geogrid can be incorporated into a thicker gravel layer to form a geogrid-stabilised gravel raft. Correctly spaced geogrid layers control the lateral and rotational movement of the gravel particles, increasing the shear strength of soil and deformation resistance of the gravel layer.

The behaviour of Tensar geogrid mechanically stabilised layers has been extensively researched. More information on this research is available from Tensar - reach out to our team today to discover more.

Tensar InterAx geogrid is the most efficient stabilisation geogrid produced by Tensar. It is ideally suited for use in mechanically stabilised rafts for mitigation of liquefaction.

.jpg)

Figure 3 - Geogrid stabilised raft for mitigation of liquefaction – incorporating multiple layers of Tensar InterAx geogrid.

Designing a geogrid-stabilised gravel raft

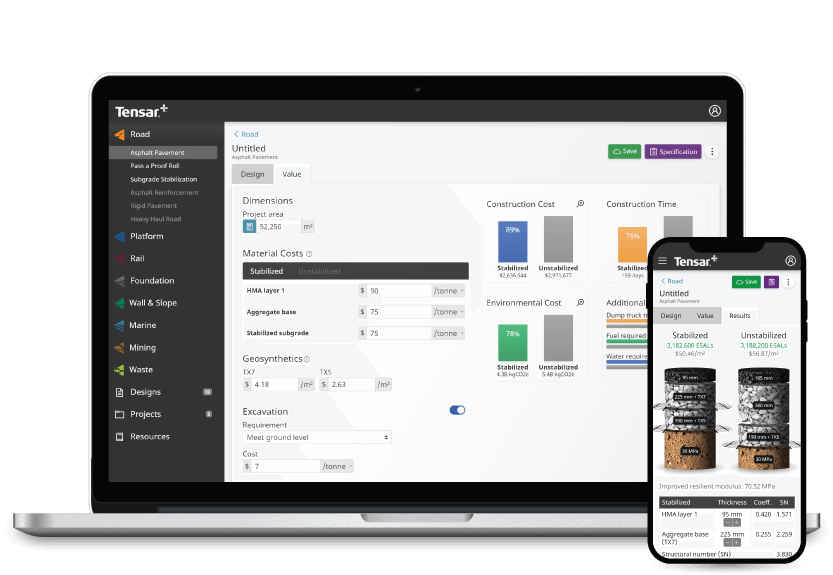

Tensar has developed design methods for stabilised gravel rafts incorporating Tensar geogrids that have been widely used by engineers for mitigating liquefaction effects below housing and low-rise structures.

The Tensar method obtains a factor of safety for a bearing capacity of 1.5 during a liquefaction event. The analysis method follows the T-value method developed by Tensar for the design of working platforms. The liquefied soil residual shear strength estimated by established methods is substituted for the subgrade shear strength. The tensile strength and stiffness of the geogrid are not input parameters in this method. Stabilisation efficiency of the geogrid is the important factor. The stabilisation effect of the geogrid on the gravel is measured and simulated in the numerical analysis.

Need more information on design tools for mitigating liquefaction?

The method has been incorporated into Tensar’s free design software package Tensar+

Real-world validation of the stabilised gravel raft over liquefiable soils

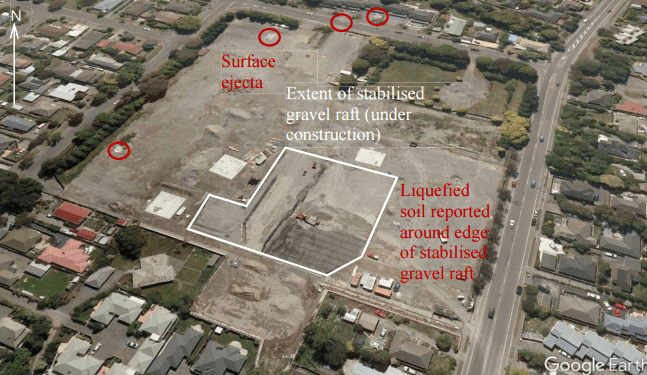

Geogrid stabilised rafts had been observed to perform well and to reduce the damage sustained to housing in multiple locations during the Canterbury Earthquake Sequence that struck New Zealand in 2011. One site in particular provided an excellent demonstration.

A geogrid-stabilised gravel raft, which would support a concrete foundation for the New World Supermarket in Christchurch, was about two-thirds complete when the Canterbury earthquake struck. The 55m2 raft was constructed over 15m of liquefiable silty sand, interbedded with non-liquefiable silts. During the earthquake, localised ejecta were observed around the perimeter of the raft and elsewhere on site, but none penetrated the stabilised raft. A survey taken after the event showed there had been no settlement of the raft caused by the earthquake.

After these events, a large-scale trial of ground improvement techniques was commissioned by the Earthquake Commission. Constructed in 2013, the trial included a geogrid-stabilised gravel raft incorporating multiple layers of Tensar geogrid. This technique proved to be effective at reducing the damaging differential settlement across the foundation. The geogrid stabilised raft method was subsequently adopted as a recommended ground improvement method in the New Zealand MBIE Technical Guidance for new housing.

.png)

Figure 4 - The New World Supermarket site following the 2011 Christchurch earthquake (Source; Lees 2022, Mitigation of liquefaction-induced differential settlement by stabilised gravel rafts)

Access design support for constructing a stabilised gravel raft

This guide has provided in-depth information about the role that stabilised gravel rafts can play in limiting building damage during seismic liquefaction events, along with guidance on the design process. Our free geotechnical design software, Tensar+, helps you design a gravel raft for your project in line with the T-Value Methodology. Tensar InterAx geogrids are also ideal for use in this type of shallow foundation. To discuss any questions you may have about an upcoming project, speak to our team today.

.png?width=400&height=400&ext=.png)