Embodied Carbon in Construction:

What It Is & How to Reduce It

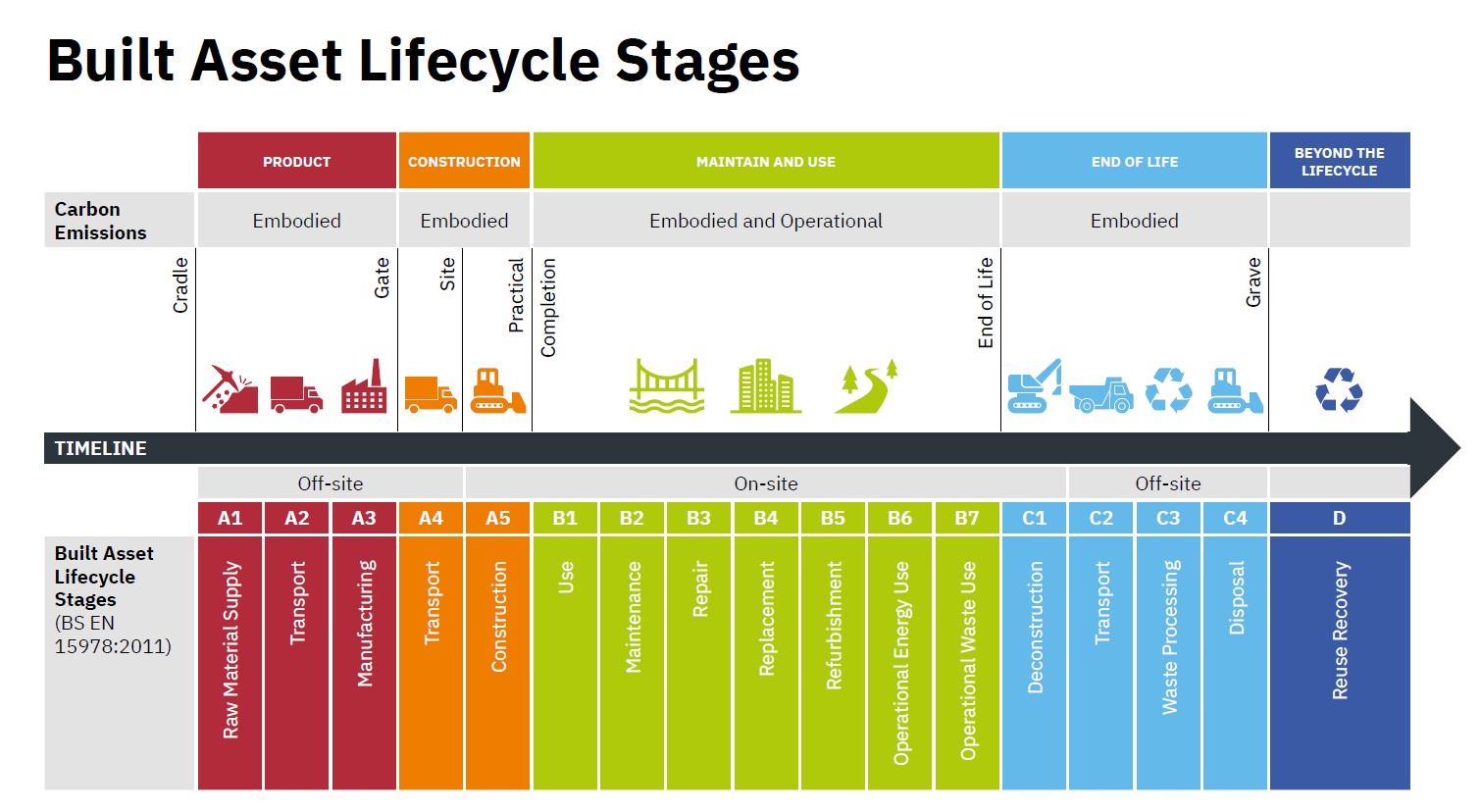

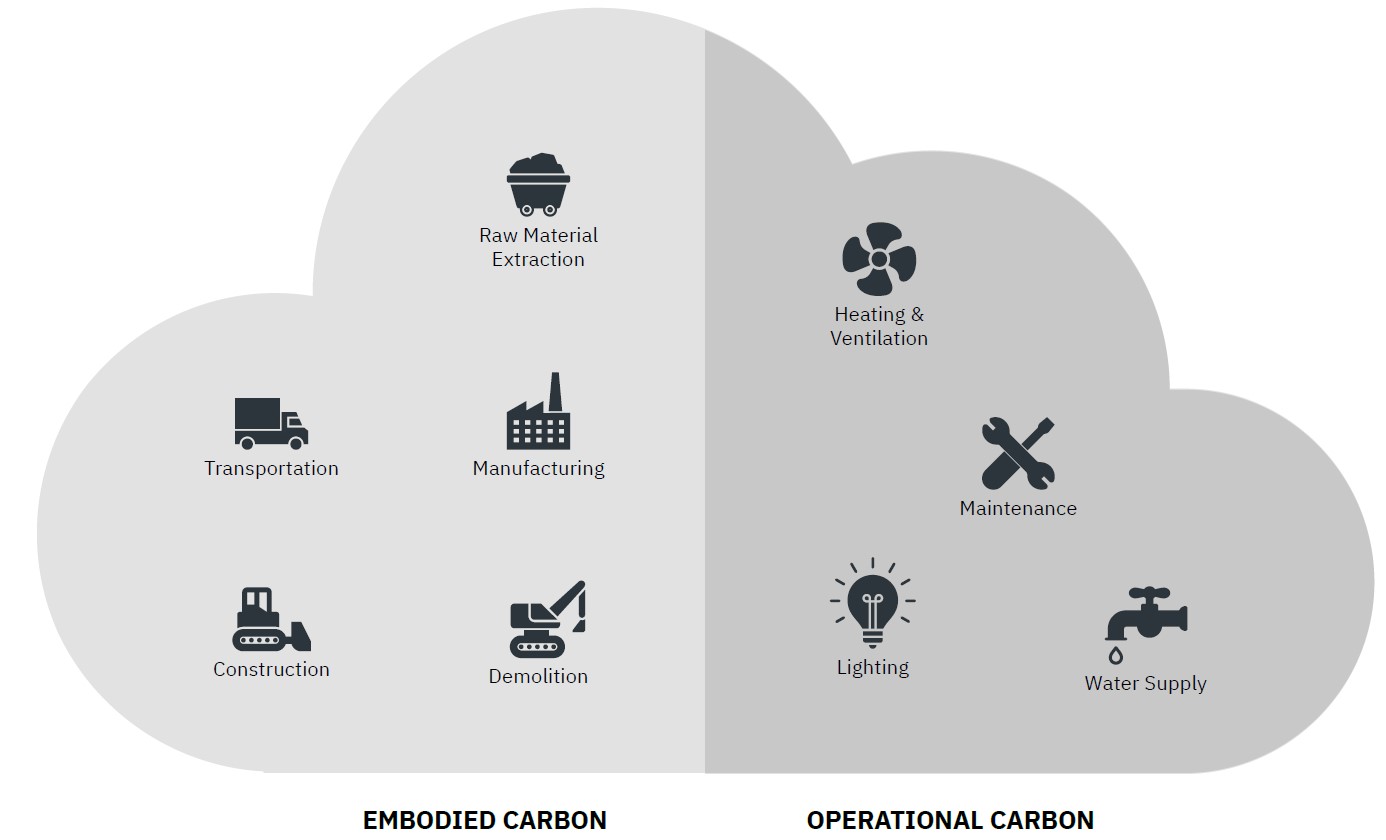

Embodied carbon in construction refers to the quantity of carbon that's emitted as part of the construction of a building or infrastructure asset, as well as adjacent processes that occur before and after construction.

Thinking first of the materials used on a construction project, we need to account for emissions from across their entire lifecycle — everything from raw material extraction and processing through to the manufacture of components, transportation at all stages, assembly, plus any post-construction repairs and replacements. Even the future disposal or recycling of the materials should be factored in, along with the carbon emissions from construction processes themselves (many of which use significant amounts of energy).

With so many individual considerations involved in calculating embodied carbon figures, it’s perhaps unsurprising that around 20% of all emissions from the built environment in the UK are currently classified as embodied. And there’s a great deal more we can be doing to reduce it. According to the UK Green Building Council, in order to meet its net-zero emissions targets, the UK should have slashed the amount of embodied carbon it was producing by 17% between 2018 and 2022. The actual reduction figure fell far short of this at just 4%, highlighting the need for more dedicated action from all parties involved.

Written by geotechnical engineering specialist, Andrew Lees, this guide explains what embodied carbon is, how to calculate it, and strategies for reducing embodied carbon in construction. It also shines a spotlight on carbon-absorbing structures, which will in their design life go on to absorb carbon, offsetting carbon than was emitted during their construction and in some cases become carbon-negative.

Looking for something in particular? Use the links below to navigate straight to it:

- What is embodied carbon in construction?

- Embodied carbon vs operational carbon

- Importance of low-carbon construction

- Reducing embodied carbon in construction

- Can structures absorb carbon – and is it possible to achieve carbon-negative designs?

- Challenges to reaching net zero carbon construction

- Case study: reducing embodied carbon with Tensar geosynthetics

- Using Tensar+ for calculating and reducing carbon emissions in construction

Looking to reduce embodied carbon on your next project? Explore Tensar+, our free software which enables you to make carbon calculations as part of the design process, or get in touch to find out how we can help.

What is embodied carbon in construction?

Embodied carbon in construction is the total amount of carbon emissions released when constructing, maintaining, and disassembling a built asset. The full lifecycle of all materials must be accounted for in calculations, along with any emissions from energy used in construction, repair, deconstruction, and disposal.

When determining how much carbon is emitted throughout the built asset lifecycle, we need to factor in each of the following stages:

- The extraction and refining of raw materials.

- The transportation of the raw materials to manufacturing plants.

- The manufacture of building materials and components (cement production alone accounts for 8% of carbon emissions globally).

- The transportation of these materials and components to construction sites.

- The construction process, including emissions from energy used to power machinery.

- In cases where repairs, refurbishment, or replacement of materials are required during the lifespan of the asset, any emissions resulting from the repetition of steps 1-6 must be factored in.

- The demolition of the asset at the end of its lifespan.

- The transportation of materials away from site following deconstruction.

- Lastly, the recycling or disposal of materials.

Calculating Embodied Carbon

To calculate embodied carbon for a material used in a built asset, you have to multiply the estimated quantity (in declared units) of that material by its carbon factor. This is usually measured in kgCO₂ per declared unit of material.

The carbon factor of a material considers the emissions released throughout its whole lifecycle, as outlined in the section above.

Once you know the carbon factors and quantities of each material involved in your construction project, you can use this formula to calculate embodied carbon:

Embodied carbon (kgCO¬2) = quantity (in declared units) × carbon factor (per declared unit)

Global Warming Potential

Man made climate change is caused by the release of several greenhouse gases, CO2 is the main gas, emitted by the burning of fossil fuels. Methane gas (CH4) arising from agriculture and landfill is second but has a much greater greenhouse effect capacity than CO2.

To simplify calculation of the combined polluting effect of different greenhouse gasses, a common index, The Global Warming Potential (GWP), is used. This index, developed by the United Nations Intergovernmental Panel on Climate change (IPCC), expresses the warming potential of a greenhouse gas in comparison with the equivalent warming from CO2. The unit used is kgCO2 equivalent or kgCO2 e.

The GWP of many commonly used construction materials can be found online. For manufactured products, reputable manufacturers will provide Environmental Product Declarations (EPDs) for their products. These will include independently certified GWP values and other environmental impact values per declared unit of product. Here is an example of an EPD for a Tensar stabilisation geogrid, Tensar InterAx.

Explore Tensar's downloadable EPDs for its products to discover more.

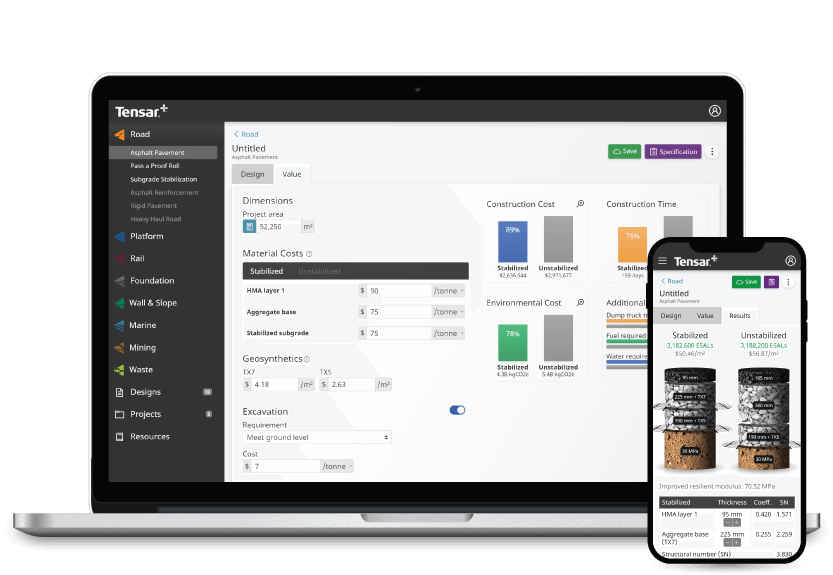

Our Tensar+ software can help you make carbon calculations and reduce embodied carbon across multiple projects, from temporary works and road construction through to working platforms, railway design, building foundations, and wall and slope systems.

Get started with Tensar+ geotechnical design software

Getting started with Tensar+ is quick, easy, and free. Simply visit the Tensar+ website and sign up for an account, then start a new design or project directly from the homepa

Start designing with Tensar+

Alongside our software, we offer innovative soil stabilisation methods that significantly reduce the quantities of high-carbon quarried aggregates on a project. Plus our geogrid reinforcement solutions, that offer lower carbon alternative solutions to reinforced concrete wall structures, whilst also helping you make more use of sustainable, sit-won materials. If your project requires the use of retaining structures, explore our range of low-carbon systems such as the TensarTech® TW1® Wall System, a sustainable alternative for construction projects.

Embodied carbon vs operational carbon

While both operational and embodied carbon in construction have an environmental impact, the factors they take into account differ. Embodied carbon refers to emissions from the construction of the built asset, including those associated with any materials used. Operational carbon relates to emissions arising from use of the built asset. For buildings, the operational carbon emissions over the life of the asset can be high, often greater than the embodied carbon. While for infrastructure assets the operational carbon emissions may be very low compared to the embodied carbon.

For roads and bridges, embodied carbon will be significant, but once opened, operational emissions are low, arising from lighting, electronic signage, pumps and management facilities. CO2 emissions from vehicle use of the asset will be high, but these are separated from the asset emissions and reported as transport emissions.

Importance of low-carbon construction

Climate change is accelerating at an alarming rate, and reducing global carbon emissions is a crucial step in the journey towards preserving our planet for future generations. At the same time, a staggering 37% of CO₂ emissions worldwide stem from the construction sector – so increasing the uptake of low-carbon construction processes is imperative.

As we’ve seen already, embodied carbon comprises a significant proportion of emissions from construction (as much as 20% in the UK). To tackle the climate crisis, then, we need joined up thinking about not only limiting operational carbon from the usage of buildings, but also making carbon savings throughout their construction, maintenance, and disassembly.

Operational and embodied carbon emissions from infrastructure projects make up a relatively small proportion of the overall emissions from all built assets. In the UK, only 6% of the total built environment emissions arise from infrastructure. Although infrastructure assets are closely linked to transportation emissions. The picture is complex in that increased infrastructure development is going to be needed to facilitate the path to net zero emissions. Renewable energy projects, power transmission and efficient transport links are essential components of a low emission future.

It is vitally important that those responsible for delivering the infrastructure developments needed to achieve net zero, strive to ensure these are low carbon projects.

Tensar has a track record of providing low carbon solutions for wind farms, battery energy storage systems (BESS), and other infrastructure projects.

Reducing embodied carbon in construction

Reducing embodied carbon in construction is key to creating sustainable and low impact built assets that can play a part in wider efforts to fight climate change. In this section, we’ll explore ways to reduce embodied carbon, from measuring carbon emissions and focusing on more sustainable infrastructure solutions to using machinery and transportation vehicles more efficiently and adopting circular economy principles.

Measuring carbon emissions

Carbon emissions can be carefully measured throughout the built asset’s lifecycle to reduce embodied carbon levels. This is also referred to as cradle-to-grave, for manufactured products, an assessment is provided in the form of an Environmental Product Declaration (EDP), that discusses a product's impact on the environment. By adopting this process, we can support stakeholders to ensure all sustainability targets are met.

Our Tensar+ software can help with this process, providing detailed carbon calculations and supporting informed environmental decision-making on your next project.

Focusing on sustainable infrastructure solutions

Sustainable infrastructure solutions can be used to reduce embodied carbon. Geosynthetics are a class of products that open up the possibility of making carbon savings across a variety of different applications, such as roads and railways. Our range includes Tensar InterAx, Tensar H-Series, Tensar Uniaxial geogrids, and TensarTech Systems. These products and systems can provide sustainable solutions, helping to improve soil stability and reduce material usage in construction projects, all while lowering overall emissions.

To discover more, head over to our guide on sustainable infrastructure solutions with geosynthetics.

Adopting circular economy principles

The circular economy paradigm centres around shifting towards a culture of reusing, repairing, and refurbishing. It also entails a shift in the way we view ownership – with a greater emphasis on sharing and leasing property.

Making the most of materials and reducing waste forms a key part of the move towards a circular economy, and achieving this in the construction sector would go a long way towards helping the UK hit its carbon emission reduction targets. As well as minimising waste, we can also reduce the embodied carbon through recycling and repurposing materials, continually extending the lifespan and value we derive from precious resources. This not only benefits the environment but also reduces waste from projects, helping construction companies to cut costs. Tensar solutions reduce the volume of quarried aggregate on a project and enable the use of recycled fill materials for the construction of roads and earth retaining structures

Using machinery and transportation vehicles efficiently

If machinery and transportation vehicles are used efficiently, this can significantly reduce carbon emissions throughout a construction project. We can achieve this by planning effectively – with efficient equipment scheduling and careful planning of transportation routes – but also by investing in more energy-efficient machinery and transport in the first place.

Can structures absorb carbon – and is it possible to achieve carbon-negative designs?

Certain structures such as vegetation-covered reinforced soil slopes can be designed to absorb carbon from the atmosphere. In addition to their carbon absorption, less embodied carbon is emitted during the construction of these slopes than would otherwise have been produced by alternatives like reinforced concrete walls.

The video below shows an example of one such carbon-absorbing structure in Hong Kong – a 60-degree slope featuring layers of Tensar geogrid reinforcement. We’ve calculated that the vegetation on this reinforced slope in Hong Kong will have potentially absorbed enough carbon to compensate for the embodied carbon emitted through its construction. And with a design life of 120 years, this will eventually go on to become a carbon-negative structure.

In this episode of Ask Andrew, Andrew Lees visits Hong Kong to answer the question, "Can Structures Absorb Carbon"

If you’re looking for naturally vegetated slope solutions to help reduce embodied carbon on a project, explore our TensarTech® GreenSlope and NaturalGreen™ systems.

Challenges to reaching net zero carbon construction

Clearly, achieving net zero carbon emissions in construction presents challenges for the stakeholders involved. These include adoption of low-carbon building materials, the cost of these sustainable options, and the carbon emissions from construction machinery and transportation of materials. Read on to discover more about these barriers to reducing embodied carbon – and what you can do to overcome them.

The use of certain building materials

Certain building materials, such as steel, cement and aluminium, can contribute to both carbon emissions and embedded carbon. Architecture2030 research shows that, globally, the built environment accounts for up to 42% of the total CO₂ emissions.

Building operations can account for 27% of this yearly, while the embodied carbon of building and infrastructure materials is responsible for 15% of this annually. To reduce construction carbon emissions from building materials, consider using low-carbon alternatives and designing structures with less requirement for high-carbon materials.

Another option is to explore the usage of site-won materials – also known as dug materials – wherever possible. Road construction is a good case in point: here, site-won aggregate can be stabilised through the interlocking mechanism of geogrids, which means the material can be recycled and no longer needs to be transported away from site. Savvy design engineers are also using waste and recycled fill in reinforced soil structures. In addition to the sustainability benefits offered by these solutions, they also provide significant cost-savings – a win-win!

Carbon-emitting construction machinery

Construction machinery can contribute to increasing carbon emissions if used inefficiently. Research by the Climate Neutral Group, CE Delft and SGS Search shows that using the rental business model for machinery can encourage efficient use and is estimated to reduce emissions by 30-50%. Wondering how to reduce carbon emissions on a construction site? The key is to monitor machinery use carefully and cut down on the intensity of operation for carbon-emitting construction machines.

The transportation of construction materials

As touched on briefly in the sections above, transporting construction materials contributes significantly to carbon emissions from fuel consumption and idling vehicles. To reduce this, scheduling deliveries and coordinating trucks and drivers effectively can minimise the waiting time the engine is turned on when not in use while reducing unnecessary vehicle trips. This not only reduces non-revenue mileage – saving you money – but also cuts down the overall CO₂ emissions. Reducing the volumes of material to be moved onto and away from site clearly has an impact on transport CO2. This should be an objective of good design. By designing to minimise the thickness of roads and working platforms, and by adopting reinforced soil wall and slope systems that can utilise use site-won material, the volume of aggregates imported, and spoil to be removed from site, is greatly reduced.

Case study: reducing embodied carbon with Tensar geosynthetics

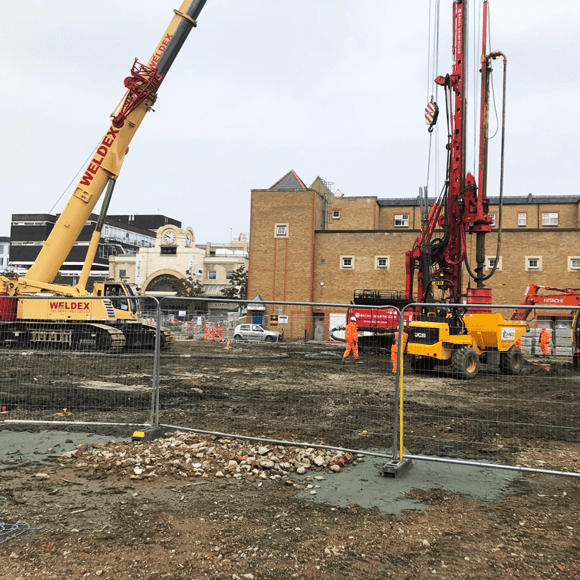

For the Marketfield Way development in Redhill, Vinci Construction UK required a 5,000m² piling mat over weak clays and underlying peat. By using Tensar’s solution, excavation and replacement of the peat was avoided, and the Vinci reduced embodied carbon in the construction. Tensar’s T-Value method was used with geogrid solutions to replace traditional construction materials.

By doing this, Tensar’s design achieved a piling mat that was 33% thinner than the original design, saved 20% in construction costs, made an 18% reduction in the construction programme, and reduced carbon emission by around 240t CO₂ e.

A piling mat used as part of the Marketfield Way project

Using Tensar+ for calculating and reducing carbon emissions in construction

This guide has explained what embodied carbon in construction is, how to calculate it throughout the entire lifecycle – from manufacturing, transporting, and disposing of materials – and the importance of low-carbon construction. We’ve also explored the difference between embodied carbon and operational carbon, the challenges faced in achieving net-zero carbon emissions, and strategies to help reduce embodied carbon levels.

If you have an upcoming project, contact Tensar's design team or submit your project details via the design support form. We can produce a complimentary “Application Suggestion” to demonstrate the value Tensar can bring to your project.

To assist you with the calculations for embodied carbon in construction throughout the entire lifecycle, our geotechnical software, Tensar+ provides comprehensive insights into how we can support your projects. For further questions and inquiries, contact us.

.png?width=400&height=400&ext=.png)