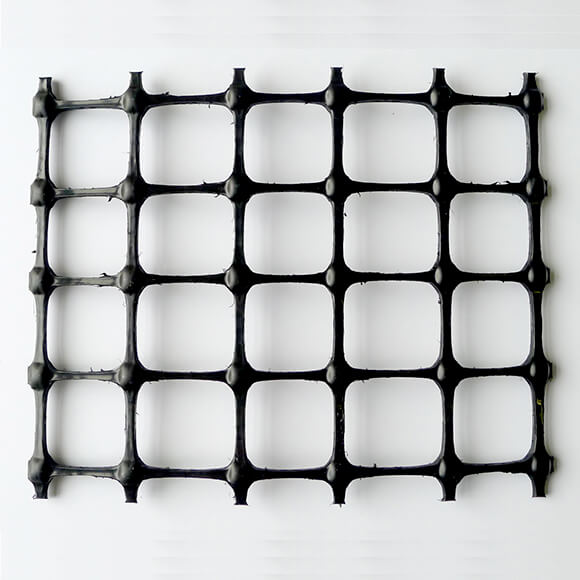

Tensar® Biaxial (SS) Geogrids

- The original geogrid for construction over weak soils

- Biaxial geogrid was invented by Tensar in the early ‘80’s

- The forerunner to Tensar® TriAx® geogrid

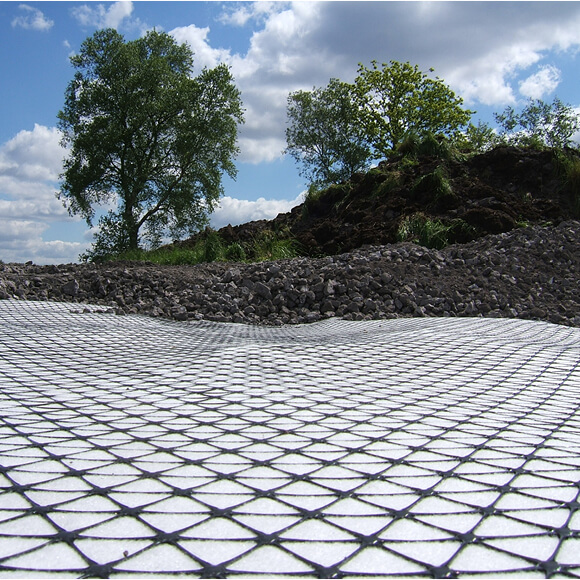

Tensar biaxial geogrids improve the stability of soils on civil engineering projects, resulting in substantial cost and carbon savings. Explore our range here, including Tensar SS20, SS30, SS40, and SSLA30.

Tensar biaxial geogrid is the original ground stabilisation geogrid. Invented by Tensar, this form of geogrid revolutionised construction over weak soils when it was first introduced for soil stabilisation back in the 1980s. Since then, Tensar SS biaxial geogrids have been used for mechanical ground stabilisation, with over 500M+ squ. metres installed globally. These biaxial integral geogrid products offer high performance and durability, making them ideal for reinforcing soils under various load conditions.

In recent years, other Tensar geogrids including triaxial and InterAx have been developed and can now offer even better value, decreasing the overall cost of a project. With decades of research, we have evolved our technology to create more advanced geogrids with a longer service life and greater cost savings.

Biaxial geogrids are available in SS20, SS30, SS40, SSLA30