BIM in Construction: Meaning and Benefits

by Matt Brown, on February 19, 2024

What is the value of BIM in construction? Well, imagine you are responsible for operating and maintaining a large office building. You can work economically and efficiently because you have access to a 3-D Building Information Model (BIM) of your entire building that includes every item, every component. You can virtually move through the building and select an item – a column, a window frame, a plumbing fixing, in fact any building component - and by clicking on it, pull up all the details associated with that item such as dimensions, materials, manufacturer, COSHH information and maintenance guidance. You can generate drawings and specifications of any component for repair or replacement.

That same model has been used by the contractor and subcontractors to generate plans, quantities, and schedules of materials to enable them to construct the building efficiently. And before that by architects and engineers to conceptualise and design the building and all its components. The model was developed by those same architects and engineers working concurrently across multiple organisations, all collaborating via that single shared model. That is the promise of fully mature BIM – Building Information Modelling. We will explore more of the benefits of BIM and how it is used in construction and geotechnical engineering below.

Read on to find out what BIM is, how BIM is used, and the benefits of BIM in construction:

- What is BIM?

- What is BIM software?

- What is Geotechnical BIM

- What are the benefits of BIM

- BIM maturity levels explained

- The different BIM maturity levels

- The future of BIM construction

- Does Tensar have BIM experience?

- Next steps

Ready to get started with using BIM for a geotechnical engineering project? Tensar’s in-house BIM team can model any of the TensarTech systems and work with the client directly in their common data environments (CDEs) – get in touch today.

What is BIM?

The BIM process enables architects and engineers to collaborate across organisations, all viewing and working from a single data location and virtual model of the project. As the design progresses, the model is developed, and the information shared between all parties. The impact on other aspects of the project, from a single change to one element, is immediately apparent to others working on the project.

Building information modelling (BIM) is more than just a set of 3D drawings. It has embedded within it, information on each of the items that make up a building. Not only the structure, but all the components – mechanical, electrical, plumbing, heating and more. That information can include dimensions, materials, construction methods, COSHH information. In fact, whatever information may be required to design, build, maintain, and eventually demolish and re-cycle the building.

Initially conceived for buildings above ground, today BIM is used for all types of structures including bridges and geo-engineering works such as Tensar’s earth retaining systems. Geotechnical BIM has evolved to capture and share a 3D representation of the ground conditions and soil properties for a project.

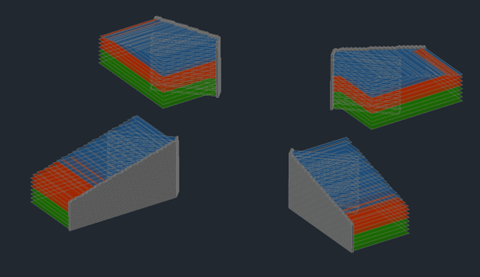

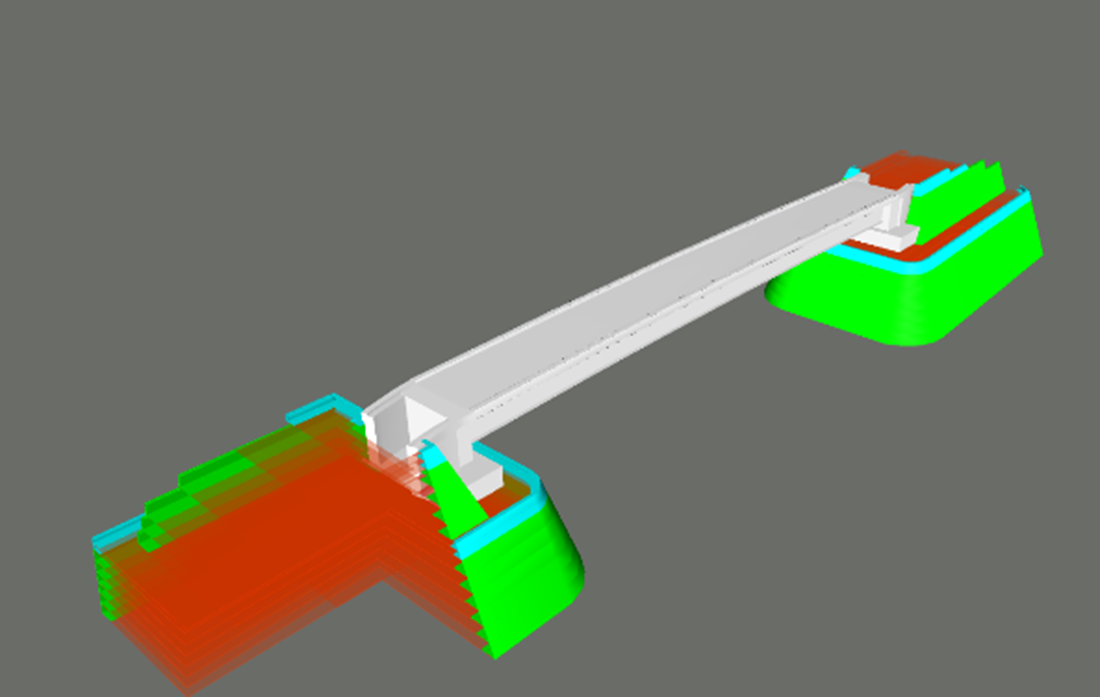

Figure 1 - 3-D modelling of TensarTech Earth Retaining Structures

What is BIM software?

BIM software is a tool to enable a digital representation of a building or structure to be created. That digital model can include functional information as well as the geometric and physical characteristics of all elements. It will usually enable integration with design tools as well as third party collaboration and communication software, typically using cloud-based platforms.

It is important to remember that BIM is a process, software tools are available to enable that process. Typically a set of software tools integrated together, rather than one single BIM software product, will be used to deliver the BIM outcomes for any project. The software tools selected may vary from project to project and should be selected to meet the needs and desired outcomes for each project.

What is Geotechnical BIM?

The use of BIM has extended beyond its use only for buildings into wider geotechnical engineering projects. The BIM process is being applied to a wider built environment, to include tunnels, dams, and other geo-structures as well as bridges and other infrastructure works. A more recent extension of BIM has seen the incorporation of geotechnical and geospatial data into a single model.

The 3-D geotechnical model is built up from data obtained from mapping, boreholes, geophysical records, geotechnical surveys, site investigation and more. The model is not static and can be updated to include information gathered from site during the construction process. This is crucial to enable the observational method to be employed – an important design approach for geotechnical engineers. Information can be extracted for input into geotechnical analysis tools, such as Plaxis, GeoStudio or FLAC. The 3-D model is of great value to engineers tasked with interpreting monitoring and observational data obtained during the construction process. The ability to visualise and share geotechnical issues within the design and construction teams add great value to the geotechnical data.

There can be some reluctance from geotechnical engineers to enter interpreted data into a shared model. Geotechnical engineering differs from other engineering disciplines in that much of the data must be interpreted from multiple factual data sources. While such interpreted data is commonly shared between site investigation companies, soils testing laboratories and geotechnical consultants, it is not normally shared with others in the project team due to a concern that it may be misused. These concerns must be overcome to achieve the full benefits of collaboration.

What are the benefits of BIM?

The greatest potential gain from implementing BIM is efficiency. Efficiency in time, cost, energy and materials -throughout the entire project life, from conception to demolition and recycling. Greater efficiency leads to improved client and stakeholder satisfaction, improved profitability and reduced waste.

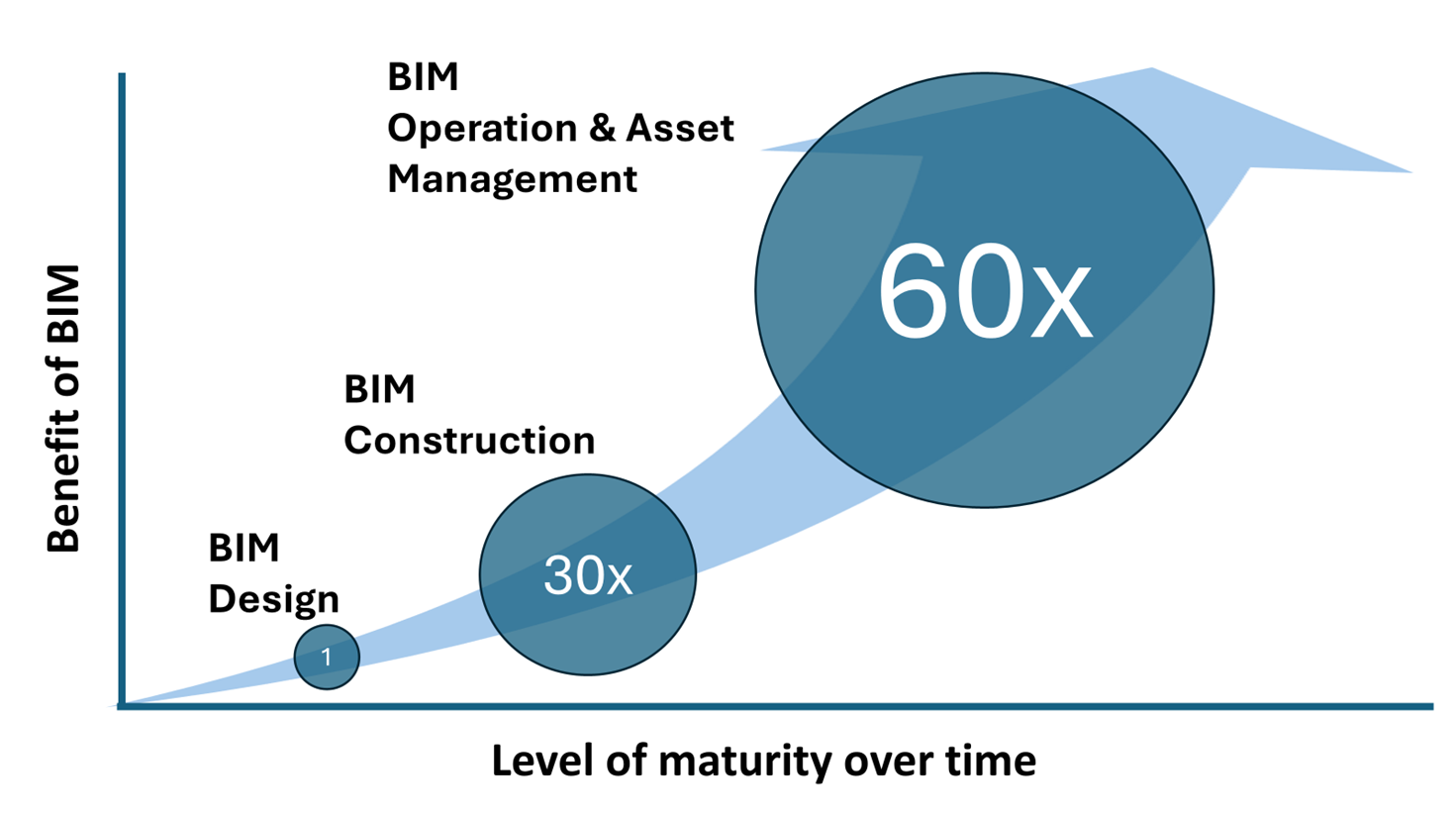

Figure 2 - The benefit potential from BIM over time (after MacLeamy)

In 2012, US Architect and BIM proponent Patrick MacLeamy set out what he saw as the potential benefits for BIM over time. He pointed out that the cost of construction was typically 20 times the cost of design, while the cost of operating a building over its life-span was 60 times greater. If the BIM process is applied through the construction stage it can deliver far greater savings than if applied only through the design stage. MacLeamy estimates saving of up to 30% of the design and construction cost. However, if the BIM process extends into the building management and operation stage, since the process is then managing a value 60 times that of the initial design stage, the potential savings are massive.

We will look at specific areas of benefit in more detail below.

Figure 3 - Benefits of Construction BIM process

Better decision making

The improved communication, clarity and transparency enabled by BIM leads to greater understanding across all participants and at all stages of the project – this in turn leads to better decision making.

Reduce risk

Access to a common project data source (a “single source of the truth”) together with increased understanding across organisations involved with the project reduces the risk of errors, and importantly reduces the cost of errors as they can be identified early. Misunderstandings can be quickly identified and resolved, avoiding compound errors that carry through into construction.

Waste reduction

The improved communication and visibility provided by BIM means there is a better opportunity to get things right the first time. But where errors are made, they are likely to be picked up early. Reducing the potential for errors in design and planning can avoid unproductive work and wasted materials.

Productivity improvement

The streamlining of processes and tasks throughout the design and construction process, reduces duplication of effort and saves valuable time. More time is available to spend on value added tasks that improve outcomes. Better forecasting, estimating and planning leads to improved productivity The increased level of specification detail and auto-scheduling available to the contractor leads to greater accuracy in the estimation of materials quantities, plant and labour requirement, saving cost and time.

Achieve sustainability goals

Greater economy and efficiencies in the construction process can deliver savings in material and energy, helping to deliver net-zero goals. Providing a common source of ‘as-built’ information that is available throughout the life of a building encourages more efficient maintenance and eventually, thoughtful planned recycling, supporting the circular economy.

Facilitate innovation

The visibility and transparency offered by BIM, coupled with the shared communication and collaboration tools, speeds up decision making, providing an environment and opportunity for innovation.

Ready to capitalise on the benefits of BIM as part of a geotechnical engineering project? Speak to our team.

BIM maturity levels explained

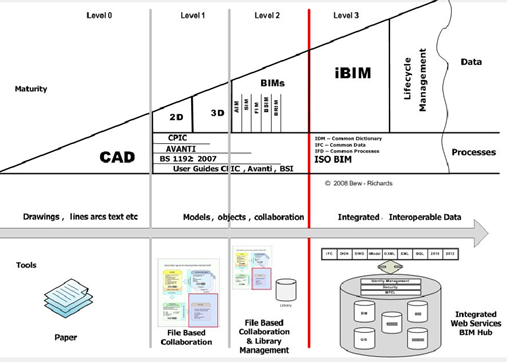

In looking at the benefits of BIM above, we saw that the potential benefits increased massively if BIM was applied throughout a bulding's life. The extended use of BIM through each stage is referred to as increasing maturity of BIM. The Bew-Richards BIM maturity model below is a useful tool to explain how BIM use can extend through different maturity levels.

Figure 4 - Bew-Richards BIM maturity model (from UK Government BIM Task Group)

The different BIM maturity levels

Level 0

Delivery and operation of the project relies on 2-D paper based information.

Level 1

Transitioning between 2-D paper based information and a 3-D environment with greater focus on information sharing and collaboration.

Level 2

A common protocol for producing, sharing and archiving information is used. However models remain discipline centric. With increasing maturity, adding metadata to the models becomes standard and integration between models takes place via a common data environment (CDE).

Level 3

At this level of maturity we see a fully integrate BIM process in place with a single model accessible to all collaborative partners. Use of the model extends from project design, through construction into maintenance and operational management.

The future of BIM in construction

The development, acceptance and use of BIM in construction is an evolutionary process. There has been no ‘big bang’ event or revolutionary change. Following on from early adopters, there are now major organisations and many large projects that are operating at level 2 BIM or even close to Level 3. Some at the forefront may even be operating at Level 3. What is certain is that the use of BIM will continue to expand and spread across the construction sector – primarily at the instigation of large client organisations. There are multiple drivers for this. The irreversible shift towards off-site manufacture and on-site assembly, the growth of 3-D printed components and structures, the increase in availability and capability of mobile devices, the growth of cloud storage and big data, plus many others. The greatest drivers will undoubtedly be the search for ever greater value from the construction industry, reduced wastage, reduced financial risk and greater speed of delivery.

Does Tensar have BIM experience?

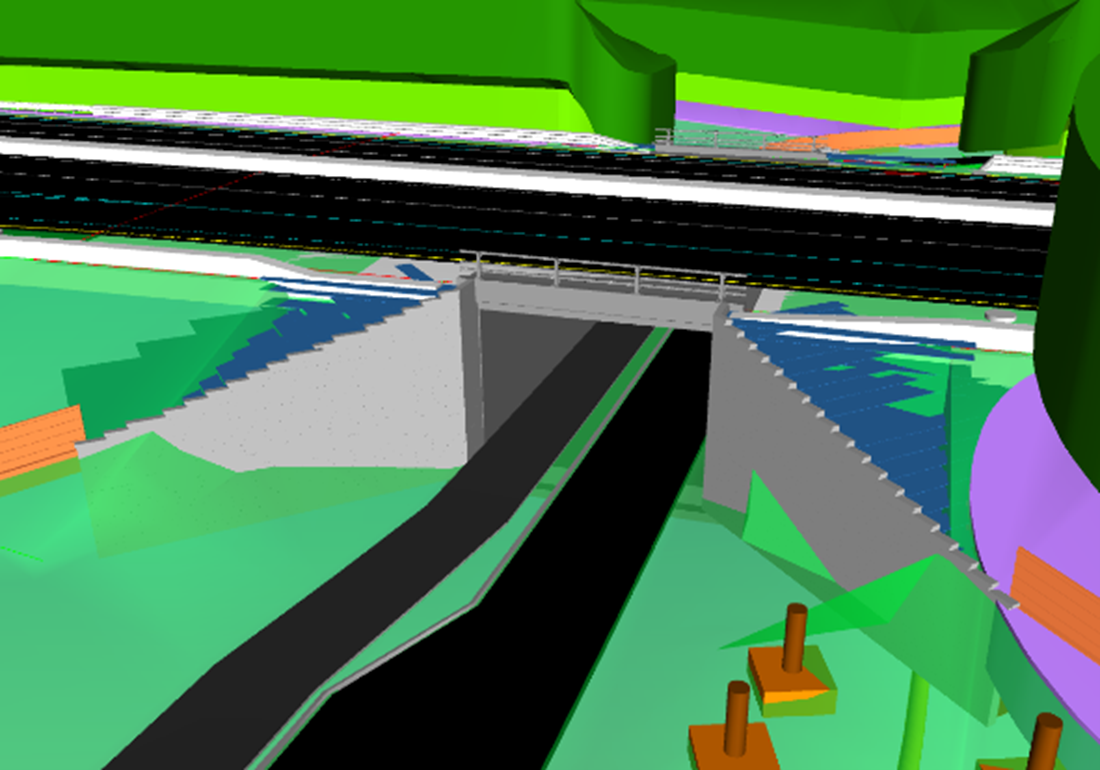

Almost all major highway projects now have a requirement to be BIM compliant and this is where the majority of Tensar's BIM compliant work has been produced. Due to the complexity of the schemes and the number of parties involved BIM has become an invaluable tool in creating the type of collaborative environment that Tensar thrive in.

Matt Brown, Tensar’s Design Services Manager for UK & Ireland says: “Our in-house BIM team has the capability to model any of the TensarTech systems and work with the client directly in their common data environments (CDEs). The major benefits come from the high level of communication and collaboration, and the shared 3-D model reduces construction risks. These models are invaluable for clash detection and elimination as they allow us to see where our structural components may clash with other structural elements or buried services saving costly design changes and delays later”.

Get in touch today if you plan to use BIM as part of a geotechnical engineering project and would benefit from our design support.

Figure 5 - 3-D modelling of road bridge for a major UK highway scheme.

Figure 6 - BIM model of TensarTech load bearing bridge abutment and wing walls for a major UK highway scheme.

Next steps

If you have a project where a BIM process at any Level is to be adopted and are seeking collaborative partners with the knowledge and capability to engage in the process, the design team at Tensar are ready to join you. Tensar has BIM capability for earth retaining wall systems, abutments and other geostructures. Find out more by contacting Tensar at TensarDesign-UK@cmc.com