Geotechnical engineering is a term you’ll probably have heard before, particularly if you work in construction, infrastructure development or land use planning.

This guide takes you through the fundamentals of the subject. Along the way, we’ll explore exactly what geotechnical engineering is, key terms you should know, the role it plays in civil engineering projects, geotechnical survey types and where Tensar fits into all of this.

There’s a lot to cover. If you’re interested in one particular area of geotechnical engineering, use the links below to navigate to it:

What is geotechnical engineering?

Geotechnical engineering is the area of civil engineering that deals with the mechanics of soils and rocks. By determining the properties of these earth materials, geotechnical engineers inform the design of many different types of structures, from roads and railways to retaining walls and building foundations. They also seek to avoid or reduce damage caused by natural hazards such as earthquakes, landslides and rock falls. Geotechnical engineering plays a vital role in civil infrastructure by helping engineers assess soil and rock behaviour to design stable foundations, slopes, and earthworks. Techniques like Value Engineering are often used in conjunction with geotechnical studies to optimise project costs without compromising safety or performance.

Geotechnics and engineering geology

Geotechnical engineering incorporates two scientific specialisms:

- Geotechnics: the application of scientific principles to solve engineering problems on or below the ground and to utilise earth materials in engineering projects.

- Engineering geology: This is concerned with applying what we know about the behaviour of rocks and soils to engineering projects.

Geotechnical vs structural engineering

Geotechnical and structural engineering are sub-disciplines of civil engineering, and both are critical to infrastructure projects. Geotechnical engineers study the conditions on and below ground, develop solutions to ground-related problems, and advise on the impact of geotechnical issues on above-ground structures. Structural engineers design the foundations and the structures above or within the ground.

Figure 1 - The role of the Geotechnical Engineer

What is a geotechnical engineer?

A geotechnical engineer is a specialised civil engineer who focuses on the behaviour of earth materials and how they interact with structures to assess the viability of construction and engineering projects.

Through site investigations, laboratory testing and modelling techniques, they assess the physical, mechanical and chemical properties of soil and rock properties to evaluate the design and stability of foundations and structures.

They also assess and work to mitigate the risks of landslides, sinkholes, earthquakes and other geological hazards to ensure geotechnical structures are economically sound, safe, sustainable and resilient to the effects of natural disasters

As you’ll see from the sections below, geotechnical engineers also offer solutions to problems that arise during civil engineering projects. Often, geotechnical engineering companies will recommend suitable geosynthetics to improve the properties of earth materials.

What do geotechnical engineers do?

As we’ve discussed, geotechnical engineers are responsible for assessing the physical, mechanical and chemical properties of the soil and rock to ensure the safety and structural integrity of civil engineering works that we see around us each day.

The types of projects they may be involved in include:

Geogrids in road construction

Site investigations for road construction

Road construction is a classic example of how geotechnical engineering can be applied.

Roads are typically built up of several pavement layers, from the road surface all the way down to the subgrade (the bottom layer). One task allotted to geotechnical engineers is to ensure that the road foundation and subgrade are sufficiently stable to support the structural pavement itself and any traffic loads travelling on it. To achieve this, they must investigate the strength and stiffness of the materials and determine whether they are strong enough, as well as looking deeper at the subsoil to assess strength, water levels and settlement potential.

Weak, unstable ground can ultimately result in pavement cracks and potholes appearing in the road over time. Rather than allowing this to happen and addressing problems later through costly resurfacing works, geotechnical engineers can prepare the underlying ground: this could either be excavated and replaced with new soil or stabilised. As an alternative, the foundation layers above can be stabilised through the addition of geogrids (a much more cost-effective and environmentally friendly solution).

See our page on the use of geogrids for roads to learn more.

Improving rail trackbed foundations

Geotechnical engineering offers valuable insights that can be applied to many other areas of transport infrastructure beyond roads. The safety, longevity and cost-effectiveness of railway lines can also be enhanced considerably by applying geotechnical principles and solutions.

For example, where the subgrade soil is weak or variable, railway trackbed stabilisation provides a highly effective and economical solution. The bearing capacity of the foundation is increased by construction of a mechanically stabilised sub-ballast layer.

Mechanical railway trackbed stabilisation

Geogrids in working platform design

Working platforms for construction projects

The construction industry also relies heavily on geotechnical engineering in working platform design. Whenever mobile cranes, piling rigs, or other heavy plant machinery are used, the team must put a suitable working platform in place to provide support and safety. The first step as always, is to investigate the properties of the ground beneath the construction site and the fill materials available, to enable the design of a safe stable platform.

Sometimes the geotechnical engineers will find that the ground is weak, requiring an expensive thick platform to provide the right level of support. In such cases, geogrids can be incorporated to stabilise the granular fill material, raising the bearing capacity and enabling a thinner platform construction, reducing costs and making the project more sustainable overall.

Building foundations

Foundations are the lowest part of a structure designed to transfer loads into the ground. Foundation design will be based on the ground conditions, not just at the surface but considerably deeper. Geotechnical engineers conduct a ground investigation to determine the properties and depth of the soils and rocks that are present as well as the groundwater conditions. They will make assessments of the bearing capacity at various depths and the likely settlement under the intended load of the structure. This information is then used by structural engineers to design the foundations. See our article on geotechnical settlement for further explanation.

TensarTech® Stratum® at Robroyston Link Road work

Embankment foundations

Earth embankments are more tolerant of total settlement and differential settlement, though the designer will need to account for this where the embankment meets a structure such as a bridge abutment. For an explanation of the different types of settlement, take a look at our video, “What is geotechnical settlement”. Where ground conditions are weak or variable, geotechnical engineers may propose reinforcement of the embankment foundation. Foundation systems such as TensarTech® Stratum® can be used to increase foundation strength and stiffness.

See our entertaining video on “Building embankments over soft soils” for an explanation of the Tensartech Stratum® foundation system. Visit our Robroyston Link Road case study to discover more about how this foundation system works in practice.

Reinforced soil slopes, retaining walls, and bridge abutments

We have seen that geotechnical engineers deal with determining ground conditions and the effect of structures on the soil below, while structural engineers deal with the design of structures above ground.

But what about where the structure is soil? Mechanically stabilise earth (MSE) structures are composed of a soil mass reinforced with layers of geosynthetic, usually a geogrid. The reinforced soil mass is internally stable and capable of carrying high surcharge loads. MSE structures are used for the construction of earth retaining walls and steep slopes, including bridge abutments. Geotechnical engineers will determine the soil properties and design these above ground soil structures. These reinforced soil structures offer considerable savings in cost, carbon and construction time compared to traditional reinforced concrete solutions.

TensarTech Earth Retaining Wall Systems, for example, can eliminate the need for crane lifts or temporary propping when constructing walls and slopes, cutting the project time and overall cost by as much as 75%. These systems are increasingly being used in abutments for motorway bridges, as demonstrated by the A14 Cambridge to Huntingdon (pictured below).

TensarTech® Earth Retaining Systems at A14 Cambridge to Huntingdon bridge abutment

Important geotechnical engineering terms

Now you’ve got a sense of what geotechnical engineering is – and where it fits into the bigger picture – let’s take a look at some key engineering terms and definitions. In the table below, we’ve highlighted a range of geotechnical engineering terms that will crop up again and again as you learn more.

| Definitions |

The capacity of soil to support the loads that are applied to the ground above (depends on soil type, shear strength, density and depth below the surface). This characteristic is used in the design of foundations. | |

The maximum shear stress that a soil can sustain without failure. It comprised two components, cohesion and friction and is dependent on the (‘normal’) stress acting perpendicular to the shear plane. | |

| The downward vertical movement of the ground due to changes in the stresses within it. Settlement is a result of the bearing capacity being exceeded or from consolidation and/or compaction of the soils beneath. | |

Consolidation | A reduction in soil volume as water in the pore spaces between soil particles is removed, usually by the application of surcharge pressure, without replacement by air. |

| The pressure of water between soil or rocks in the gaps between particles. It is affected by soil type, surcharge, water flow conditions and water table level, and influences shear strength. | |

| The capacity of soil to allow water to pass through it – this depends on factors like the shape and texture of soil particles and the relative volume of voids in the soil (voids ratio). | |

Compaction | The densification of soil, with a reduction in pore spaces, by the application of external stress. Typically, due to mechanical loading, or surcharge. |

| A polymer product with an arrangement of integrally connected tensile ribs that form a grid structure with open apertures. Used to improve the properties of soils and aggregates in a range of civil engineering projects. | |

| A broad product classification that includes geogrids, geotextiles and geomembranes alongside other minor categories. Manufactured from synthetic materials they are applied to solve of geotechnical problems Geogrid is a commonly used type of geosynthetic. |

Geotechnical surveys

Geotechnical surveys are at the core of a geotechnical engineer’s role. Also known as a geotechnical or ground investigation, this is the process of sampling and testing the physical properties of soil and rocks. A 3-dimensional map of the ground is developed by exploration using boreholes, trial pits, and non-intrusive geophysical measurements. Samples will be retrieved and tested for the geotechnical survery. The data from these tests is then used to inform design decisions in civil engineering projects and assess the feasibility of the proposed construction methods.

When investigating the soil and rocks on-site as part of a geotechnical survey, the following critical factors are typically assessed:

- Consistency

- Structure

- Strength

- Drainage characteristics

Geotechnical surveys should always be accompanied by a geoenvironmental investigation, which looks into the chemical properties and possible contamination of the soil and groundwater to assess the potential impacts of the project on humans or the environment. Geotechnical engineers will be involved in specifying remedial measures where an environmental threat has been identified.

Types of geotechnical testing

Many different types of geotechnical tests are used to measure the soil and rock characteristics outlined above. Whilst a comprehensive look at these tests is beyond the scope of this article, the next few sections explore the most common examples that you’ll hear about in geotechnical testing.

Figure 2 – Geotechnical testing – Soil consolidation test

Consolidation testing

Consolidation tests are used to determine how far and how fast a column of soil will change in height when an axial load is applied to it and water is expelled from the pore spaces between soil particles; in geotechnical engineering, this change in height is known as consolidation. The specimen in consolidation testing will normally be saturated soil in a cylindrical form.

Triaxial testing

This type of test is used to determine the mechanical properties of soil, rock, or granular material. The aim of a triaxial test is to establish the shear strength of a sample by replicating the in-situ stresses it would experience in the ground where it was taken from. This is achieved by applying a confining stress to the sample. The cylindrical sample is enclosed within a rubber membrane and placed in a water filed cell. The water is pressurised to replicate the stress conditions underground, while a vertical load is applied to shear the sample. Sample size usually ranges from 38mm to 100mm diameter but for bigger aggregate particles a larger sample is required. Tensar uses a sample size of 500mm diameter when testing soil stabilised with Tensar triax geogrid to obtain meaningful data.

Head over to our guide on triaxial tests to learn more.

Figure 3 - Geotechnical testing - Triaxial test

Figure 4 - Geotechnical testing - Direct shear test

Direct shear testing

A relatively simple test that can be performed on undisturbed or remoulded samples. The purpose of a shear test is to determine how rocks or soils will respond to shear stress (that is, a parallel force applied to the material). From this type of test, we can work out the shear strength of soil – its resistance to deformation by tangential (or shear) stress. The sample is placed in a shear box and subjected to vertical pressure. The upper section of the shear box can be moved relative to the bottom, shearing the sample at the interface. The force needed to do this is measured and from this the shear strength can be calculated.

Permeability testing

Assessing the permeability of earth materials is a vital component of geotechnical testing. Permeability influences pore pressure dissipation when soil becomes saturated with water, which in turn impacts how fast the soil consolidates, its rate of strength gain and its rate of settlement. These are all key elements of the stability of earth structures.

In a laboratory environment, there are two main types of permeability tests: the Falling Head Test and the Constant Head Test. In-situ drainage tests can also be carried out in the field.

Visit our guide on the permeability of soils to learn more about how these work in practice.

Figure 5 - Geotechnical testing - Constant head permeability test

Figure 6 - Geotechnical test - California Bearing Ratio (CBR) Test

California Bearing Ratio (CBR) testing

California Bearing Ratio (CBR) testing is a penetration test, widely used in the design of flexible pavements. The output is a CBR value, which provides a useful estimate of soil strength and surface stiffness. CBR value is expressed as a percentage that represents the sample result compared with a standard, high-quality granular material in identical testing.

Learn more about the CBR test in our guide to understand CBR values and their significance in road pavement design.

Plate load test

This type of performance test can be carried out in the field. It measures the soil response to a vertically applied load. If the load applied is high enough, it can measure the bearing capacity of the soil. The name derives from the circular steel plate, which is used in the test to apply load to the soil and induce settlement.

When it comes to working platforms, it can be useful to test for bearing failure. A large diameter plate is needed to accurately represent the working conditions, which requires enormous loads to reach failure. Tensar has commissioned very large scale plate load tests to validate its stabilised working platform design method, known as the T-value method.

Keen to learn more? See plate load tests – uses, plate size and interpretation.

Figure 7 - Geotechnical testing - Plate Load Test

Geotechnical reports

A geotechnical report communicates the results of tests carried out on rocks and soil. It will also contain clear recommendations explaining exactly how the site conditions must be factored into the design and construction process.

For example, based on test results, a geotechnical investigation company may recommend a certain depth for the excavations beneath a building and highlight the need to pump out groundwater intermittently due to the drainage characteristics of the soil. The report may also lay out other considerations such as the requirement for certain types of pile foundation and the design values relating to pavement design.

As you may have gathered, the outputs of geotechnical reports can be many and varied. These will depend on the type of project you are working on and the characteristics of the earth materials that are present.

Where does Tensar fit in?

We’ve discussed the role that geogrids can play in stabilising earth materials for various different civil engineering works. This polymeric geosynthetic was invented by Dr Frank Brian Mercer OBE FRS in the late 1970s and early 1980s and manufactured by his company Netlon, which went on to become Tensar.

Today, we are still the world leaders in geogrids, researching and developing innovative new product designs such as Tensar InterAx and transforming how civil engineering projects are carried out. Our geotechnical engineering solutions are relied upon in a wide range of industries, from residential and commercial construction to renewable energy and airport design.

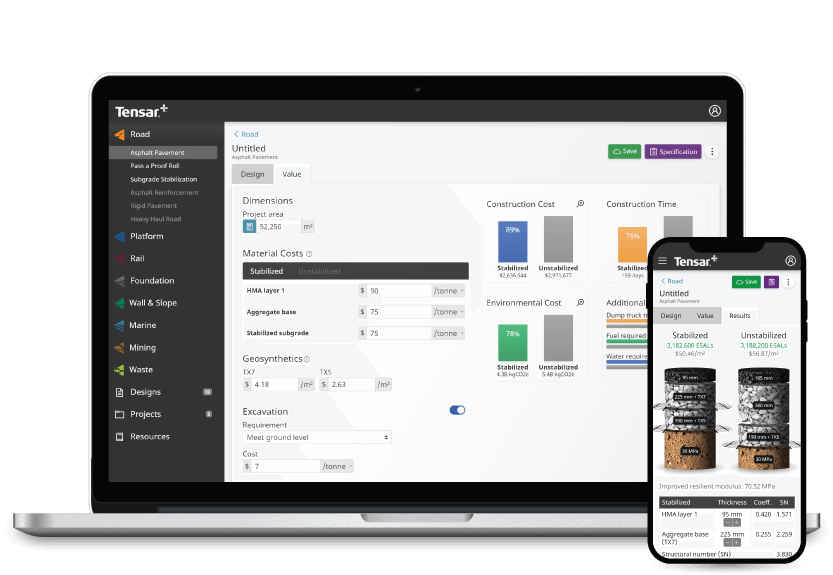

Tensar is also a global innovator in geotechnical design software. Our free-to-use design platform, Tensar+, can be accessed online anywhere, anytime. This best-in-class solution enables engineers to design mechanically stabilised layers for road foundations, pavements, working platforms and rail trackbed, other Tensar software enables the design of reinforced soil walls, slopes and bridge abutments.

- Design and evaluate project specifications.

- Compare alternative materials and project conditions.

- See the cost and time savings in real time.

- Analyse the sustainability of projects.

Next steps

Over the course of this guide, we’ve taken a close look at exactly what geotechnical engineering is, its many applications, the tests involved, and the role that geotechnical surveys play in ensuring the safety and longevity of civil engineering works. Contact us if you have any questions or enquiries about geotechnical engineering.

If you’ve found this introduction to geotechnical engineering useful, you may want to take a look at some of our other more in-depth articles: