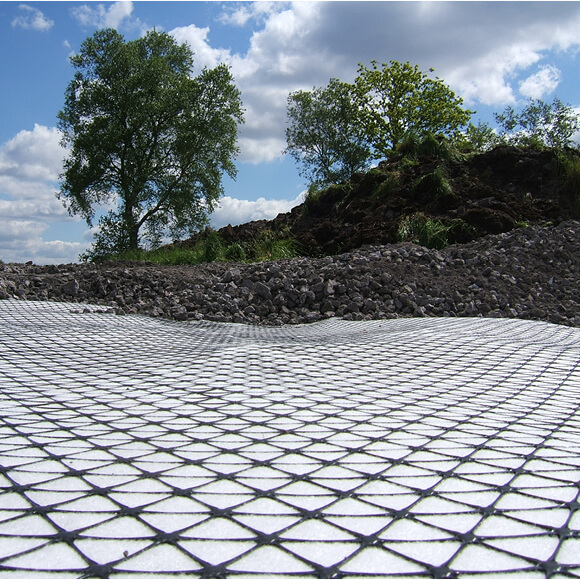

Tensar® TriAx® (TX-G) Geocomposite

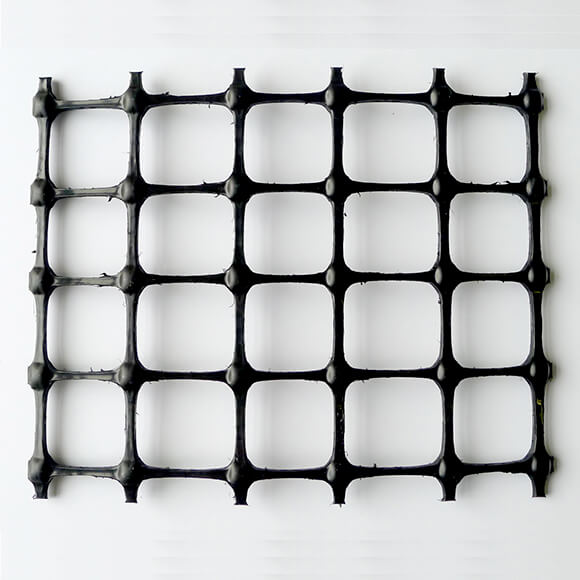

- Incorporates Tensar TriAx® geogrid for proven soil stabilisation performance

- Paired with a high-quality needle punched geotextile for separation and filtration

- Laminated together for ease and speed of installation

- Three functions in one quality product

The Tensar TriAx® geocomposite line offers stabilisation, separation and filtration by combining geogrids and geotextiles. You’ll find spec sheets for the key products in this range here, including TX160-G, TX190L-G, TX190L-GN and TX150L-G.

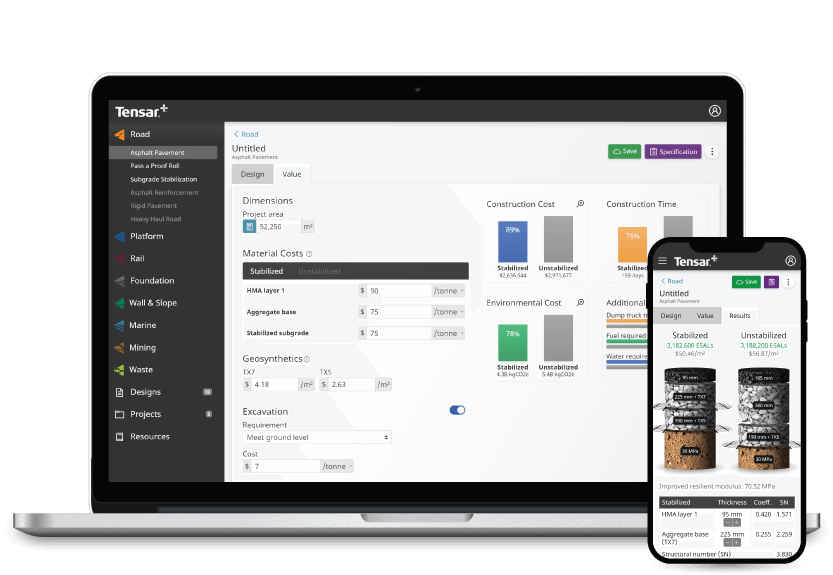

Need a Tensar design for your project?

Request a free design assessment to discover how our geogrid solutions can enhance the longevity and increase the value of your unpaved roads, pavements and trafficked areas project.

Tensar TriAx TX-G products incorporate the advanced technology of the TriAx geogrid, combined with a non-woven geotextile. The two components are factory-bonded, to create a geocomposite structure. As well as the primary function of stabilisation, this process also provides additional separation capability and filtration.

The high degree of separation and filtration prevent fine subgrade particles migrating up into the aggregate layer, which would otherwise affect the stabilisation and drainage performance.

Tensar TriAx TX-G solutions are available in TX130S-G, TX150L-G, TX160-G and TX190L-G.