Road & Highways

Helping highways construction budgets stretch further

Roads Authorities, whether local or national, face the monumental task of building and maintaining the roadways of their communities. Engineers designing new roads and public road improvements seek to deliver safer, better, longer-lasting roads more economically, more sustainably and with greater climate resilience.

Those responsible for maintaining existing road and highways networks face a widening gap between the needs of a deteriorating network and squeezed maintenance budgets. With materials and labour costs continuously rising and the scope of their responsibilities constantly expanding, how do road authorities keep up?

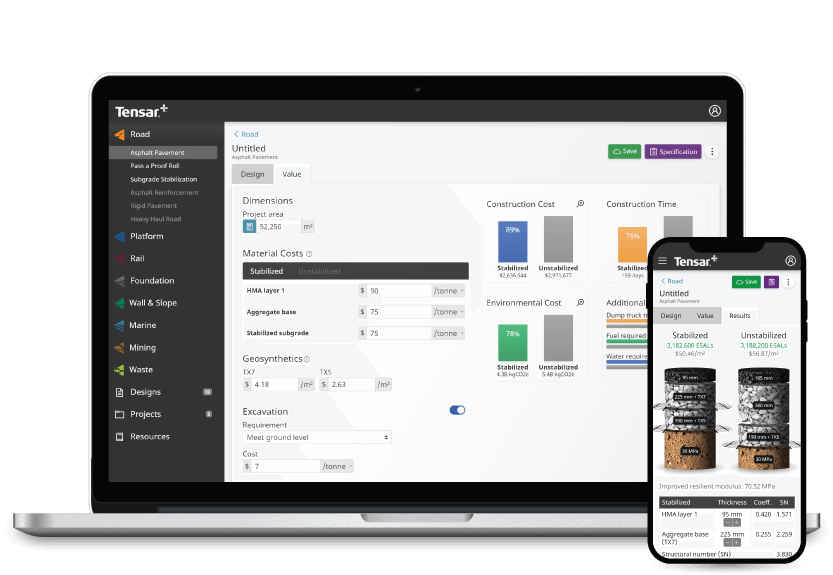

Tensar has been helping road authorities with public road improvements and highway construction for many years, becoming an industry leader in reliable road and pavement projects. We can help stretch pavement, earthworks, and bridgeworks budgets further by using our proven technologies, supported by Tensar expertise and software.

Road Foundation

The performance of a pavement is directly influenced by the quality and longevity of the road foundation beneath it. Designers of roads over weak or variable soils must consider how the road construction is established, as well as the materials and layer thickness required to provide a strong and stable foundation. Protection of the subgrade during road construction is also important. Deformation, rutting and re-moulding of the subgrade have an impact on strength and water retention, affecting the performance and longevity of new pavement and road formation.

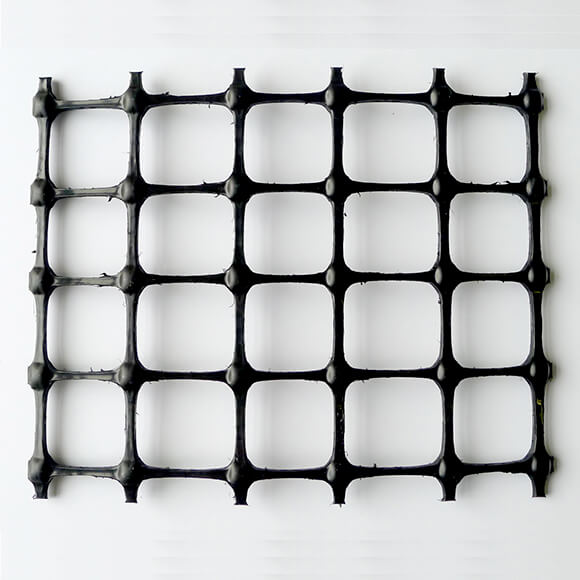

Tensar geogrids can improve the long-term performance of roads, pavements, trafficked areas and unsurfaced roads foundations by protecting the subgrade during construction, and stabilising the capping layer and/or subbase layers to provide the best possible road construction. By stabilising and strengthening the foundation layers, the thickness of both the capping layer and subbase layers can be reduced, thereby saving on road construction costs. It also reduces excavation, materials consumption, transportation to and from the site and carbon emissions, giving a longer-lasting more sustainable and resilient road construction.

Need an foundation design for your road project?

Tensar’s design team can produce a free of charge “Application Suggestion” to illustrate what Tensar can achieve and how much value can be added to your project.

Request Design Assessment

Road Pavements

Pavement designers choose Tensar technology to improve the service life of new pavements, or to enable a reduced pavement thickness. A Tensar soil stabilisation geogrid is designed into the road formation, located below or within the unbound layers to control aggregate movement. This reduces deformations and increases pavement strength within the pavement section, improving and maintaining stiffness.

By reducing pavement thickness, savings are achieved in materials and transportation costs, road construction time, and carbon emissions. Increasing the service life of a pavement reduces future maintenance requirements and lowers the whole-life cost.

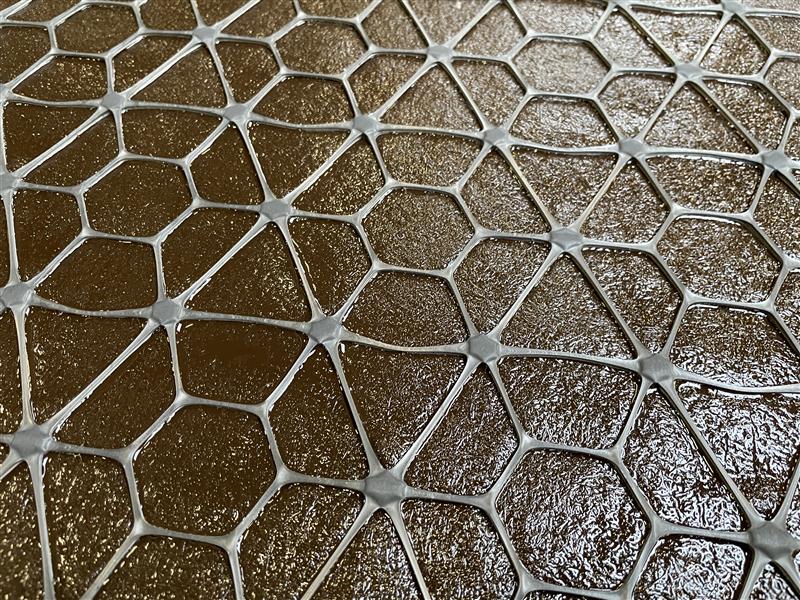

As well as in the unbound layers, there is potential for improving the efficiency of the asphalt layers in flexible pavements. Tensar asphalt interlayer products can be incorporated within the asphalt layers to improve the fatigue performance of the asphalt. This allows the designer to consider thinner asphalt layers for a given level of performance. Reducing asphalt thickness has a significant impact on overall pavement and road formation costs. Alternatively, increasing performance levels will see benefit from a reduced whole-life cost.

Pavement Maintenance

Conventional pavement maintenance strategies often involve the placement of an asphalt overlay over the pavement surface to re-seal and increase life. However, cracks or joints in the existing pavement will often reflect through into the new overlay, reducing its effectiveness and shortening life, and often the only solution is thicker and thicker overlays.

The inclusion of a Tensar asphalt interlayer below the overlay can intercept cracks, such as potholes, delaying their propagation and increasing the life of the overlay. The cost per kilometre per year of the overlay treatment is greatly reduced. Paying a little more for the asphalt interlayer to be incorporated has a disproportionately greater effect on the overall cost.

Need an asphalt design for your road project?

Tensar’s design team can produce a free of charge “Application Suggestion” to illustrate what Tensar can achieve and how much value can be added to your project.

Request Design Assessment

Earthworks and Bridgeworks

Almost all highway construction projects involve the construction of retaining walls, road embankments, bridge abutments, and other features. Roads Authorities and highways contractors have long appreciated the many advantages of Tensar reinforced soil solutions. Tensar has a range of solutions for retaining wall systems, steep embankments and bridge abutments. These road and highways improvement solutions offer major cost advantages and construction programme advantages over alternative construction methods. They also enable the use of recycled or site-won fill materials to keep down costs and minimise local impact. Tensar also has innovative solutions for the construction of embankment foundations over weak soils, which can be quicker to construct with a reduced land take and controlled settlements. Eliminating the need to remove weak foundation soils can also help achieve balanced cut & fill earthworks.

Need a wall or slope design for your road project?

Tensar’s design team can produce a free of charge “Application Suggestion” to illustrate what Tensar can achieve and how much value can be added to your project.

Request Design Assessment

Full Depth Road Improvement

With increased materials costs and sustainability targets, the recycling or reuse of road improvement materials has become an imperative. Full-depth road rehabilitation is gaining acceptance and is being widely used in many regions. Existing pavements are pulverised, re-laid and compacted prior to resurfacing with new asphalt or surface dressing. In some cases, a new binder in the form of bitumen or cement is added during the process. Including a Tensar Triax (TX) geogrid in the design below the recycled road layer improves compaction and strengthens the rehabilitated pavement to increase service life.

Expansive Soils

Some Roads Authorities have to contend with expansive clay soils, potentially severely impacting the life of new pavements by the shrinkage and expansion movements associated with moisture changes in these soils. This is usually experienced in the form of premature cracking along the length of the road surface. Designing Tensar stabilisation geogrids into new pavements has been proven to mitigate against the effects of shrinkage, greatly increasing the lifespan of roads through subgrade stabilisation.

Even Better Value

What if you could design higher-performing pavements more sustainably, and with greater resiliency - without increasing costs? What if you could extend pavement service life by up to 200%, or increase the life of an overlay, to reduce the cost/km/year of a resurfacing intervention? All of this is possible with road construction and highway reinforcement from Tensar.

The pavement surface may be the public focus of a highway, but the network is founded on major earthworks, embankments and bridgeworks. Structural and geotechnical engineers working in road and highway construction are faced with the same pressures to deliver more for less. They also seek to design more economically, more sustainably and with greater resilience. The goal is to construct highway embankments with a reduced footprint, more quickly and with reduced carbon emission, and bridge decks without high maintenance bearings, seated directly on lower-cost reinforced soil abutments using recycled fill. Tensar has proven innovative solutions for pavements, earthworks, and bridgeworks - supported by Tensar expertise and software.