Railway Infrastructure – Construction & Maintenance

Helping rail authorities stretch budgets further

Rail Engineers designing new railways seek to deliver safer, better, longer-lasting railways more economically, more sustainably and with greater climate resilience. Those responsible for maintaining existing rail networks face a widening gap between the needs of a deteriorating network and squeezed maintenance budgets.

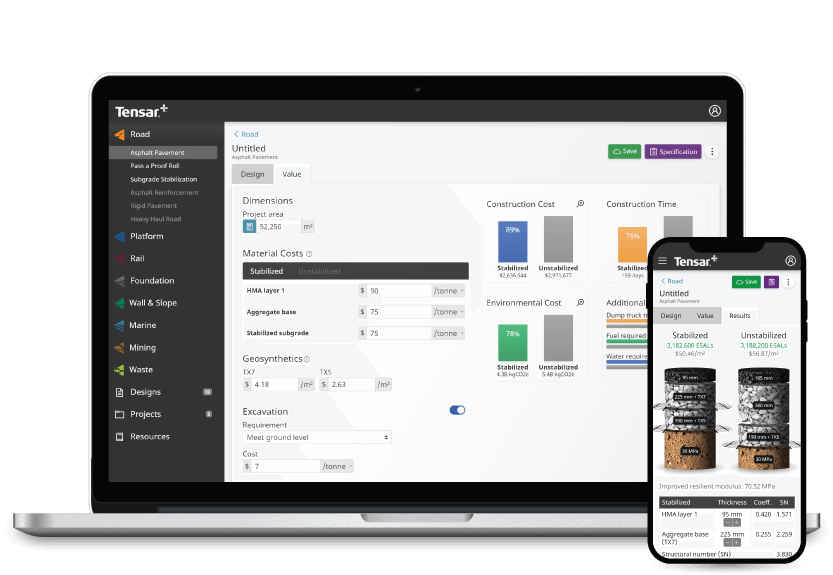

With materials and labour costs continuously rising and the scope of their responsibilities constantly expanding, how do rail authorities keep up? Tensar helps railway authorities stretch rail trackbeds, earthworks, railway embankments and bridgeworks budgets further, by using our proven technologies - supported by Tensar expertise and software.

Railway Embankments

Earth embankments are an essential component in railway infrastructure. Embankments raise the track level above the ground level and enable a smooth track alignment to be constructed over undulating terrain. Approach embankments gradually raise the track up to bridge deck level at road and river crossings. The long-term stability and settlement of embankments, particularly over weak soils, present railway engineers with geotechnical challenges. Tensar has solutions that address these challenges for embankment foundations and slope stability.

TensarTech Stratum cellular foundation mattress and Tensar Basetex high strength geotextile can be used to construct stable embankments over weak soils, enabling faster construction and reduce long term settlements. The land-take below embankments can be reduced by steepening embankment slopes using Tensar reinforced soil systems. Stable, naturally vegetated slopes, up to 70° are possible with TensarTech GreenSlope systems, greatly reducing the construction footprint.

Railway Retaining Walls

Railway retaining walls are fundamental to rail networks, protecting rail tracks at a lower level, supporting elevated rail tracks, and forming wing walls and bridge abutments. Retaining walls on railway lines can be especially effective where space is restricted, allowing the construction footprint to be minimised in areas such as high-density urban areas.

TensarTech Earth Retaining Wall Systems, allows Rail Authorities to choose a rail retaining wall system that is visually attractive, rapid to construct and is significantly lower in cost compared to reinforced concrete alternatives. In addition, TensarTech systems usually require no deep foundations, reducing construction time and local disruption.

Need a retaining wall or slope design for your rail project?

Tensar’s design team can produce a free-of-charge “Application Suggestion” to illustrate what Tensar can achieve and how much value can be added to your project.

Request Design Assessment

Rail Track

What if you could design higher performing trackbed more sustainably and with greater resiliency - without increasing costs? What if you could extend trackbed service life or greatly extend the periods between routine maintenance?

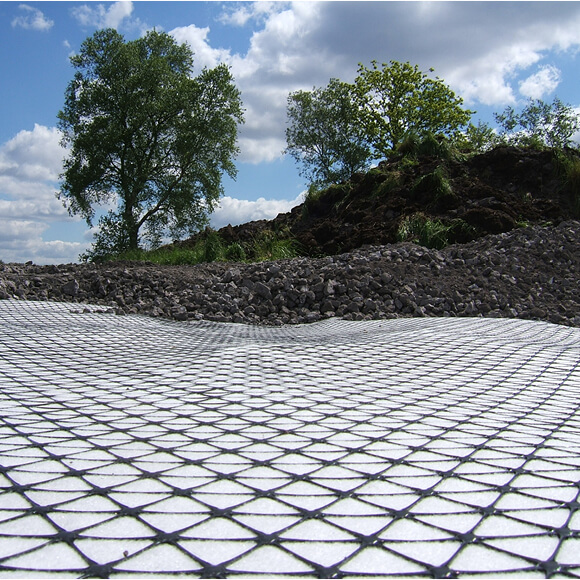

The trackbed provides support to the rails and transfers the train loading down into the soil beneath. Design of the trackbed needs to ensure that the bearing capacity of the ground is not exceed and that settlements are minimised and controlled. The inclusion of Tensar stabilisation geogrids improves the bearing capacity and helps control differential settlement. This is essential to maintain track speeds and reduce maintenance requirements and the disruption that can cause to the network.

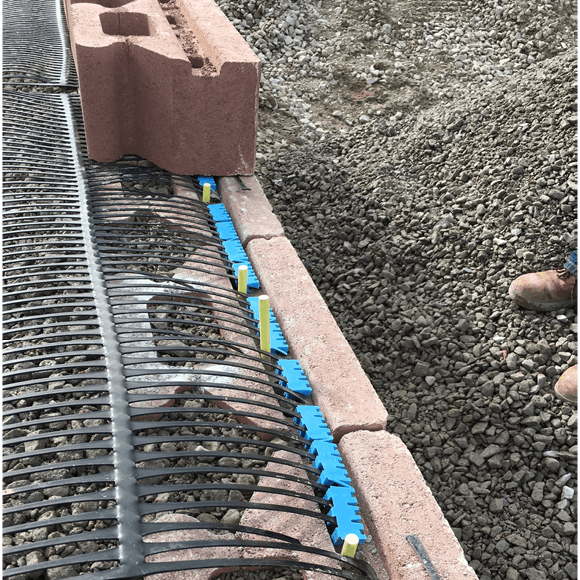

Ballasted track requires periodic tamping to maintain the track alignment. The frequency of maintenance can be extended by reducing the lateral spreading and degradation of the ballast layer that results from regular use. Stabilisation of the ballast layer with Tensar geogrid controls ballast movement and the associated degradation, extending periods between maintenance, helping to maintain track speeds, and reducing disruption to the network.

Tensar has proven innovative railway solutions for trackbed, earthworks, and bridgeworks - supported by Tensar expertise and our intuitive cloud-based software, Tensar+.

Even Better Value

An efficient rail network must maintain design speeds and minimise service disruptions for major maintenance operations. The quality and durability of the trackbed are critical, both in determining safe operating speeds and in minimising maintenance-related disruption.

Throughout the railway track construction process, including new track and track reconstruction works, the bearing capacity and stiffness of the trackbed foundation can be improved by incorporating Tensar stabilisation geogrids into the sub-ballast layer. In ballasted track, the time between necessary tamping maintenance can be significantly increased by incorporating Tensar stabilisation geogrid in the base of the ballast layer. Ballast degradation and track settlements are reduced, maintaining track speed and extending maintenance cycles.

Earthworks and Bridgeworks

Almost all rail projects involve the construction of retaining walls, road and rail embankments, bridge abutments, and other features. Tensar has a range retaining wall systems, steep embankments and bridge abutment solutions. These solutions offer major cost advantages and construction programme advantages over alternative construction methods. They also enable use of recycled or site-won fill materials to keep down costs and minimise local impact.

Additionally, Tensar has innovative solutions for the construction of railway embankment foundations over weak soils. These can be quicker to construct, with a reduced land take and controlled settlements.